Ontario has a strong reputation as one of the aerospace industry leaders in Canada and globally. The sector contributes around $6.5 billion annually to the economy, accounting for 30% of Canada’s aerospace sector.

Ontario’s aerospace industry plays a critical role in global supply chains. Although one can find components manufactured in the province in virtually every commercial aircraft worldwide, the region is specifically renowned for its leadership in landing gear systems.

Global Integration of the Aerospace Industry

The aerospace industry is a highly complex and globally interconnected network that allows for procuring specialized materials and components that may not be available locally, enabling the industry to leverage global expertise and innovation.

Aerospace manufacturing involves sourcing thousands of individual components–including the aforementioned landing gear parts from Ontario–from a worldwide network of suppliers. The global aerospace industry, including industry leaders like Lockheed Martin, relies on tiered suppliers, logistics providers, and regulatory bodies across multiple countries to ensure seamless production and assembly.

Example: Joint Strike Fighter

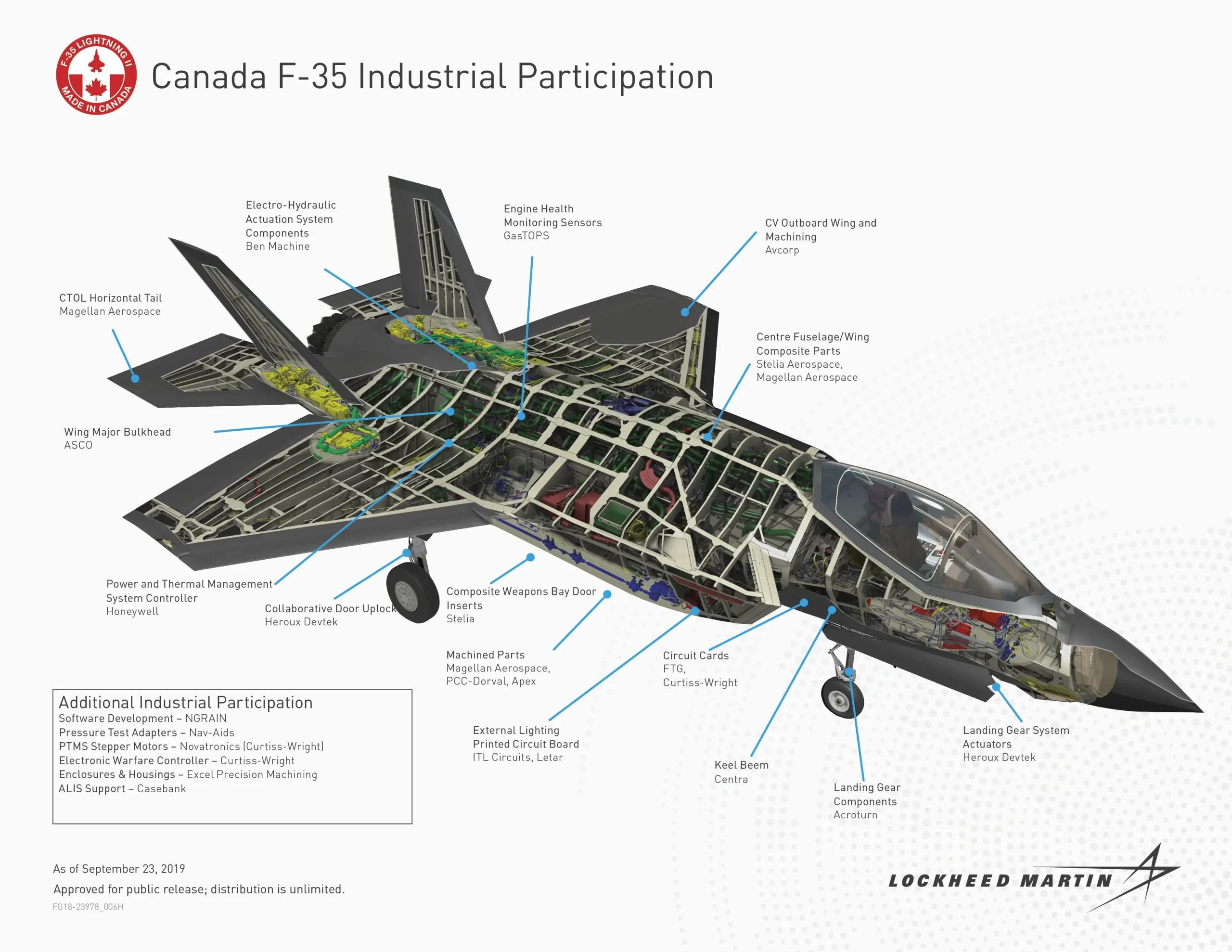

The Lockheed Martin photo below illustrates Canada’s participation in the Joint Strike Fighter (JSF) program since its inception in 1997. Canada’s involvement ensures interoperability with key allies like the U.S., UK, and NATO members, as the F-35 is central to allied defence strategies.

Canadian companies have secured significant opportunities through the JSF program– by 2019, these contracts were worth over $1.3 billion. These include work on airframes, engines, advanced composites, and Ben Machine’s contribution to the electro-hydraulic actuation system components.

The program has created skilled jobs and boosted Canada’s aerospace sector by integrating Canadian firms into the global F-35 supply chain.

This illustration of the Lockheed Martin Joint Strike Fighter highlights the numerous manufacturing partners that developed parts for the vehicle, including Ben Machine’s participation in the electro-hydraulic actuation system components.

Importance of International Collaboration

The industry relies on complex global aerospace supply chains, making it especially vulnerable to trade restrictions. Global trade policies, such as tariffs, disrupt procurement strategies and delay sourcing parts from international suppliers. Tariffs profoundly impact aerospace manufacturing, influencing costs, causing supply chain issues, reducing competitiveness, and affecting market dynamics.

These challenges raise prices, reduce international competitiveness, and alter market strategies. The effects ripple through the industry, impacting manufacturers, suppliers, and consumers.

Most importantly, tariffs introduce significant friction into the aerospace industry’s global trade network by destabilizing supplier relationships and forcing companies to adapt their sourcing and contractual strategies. These disruptions underscore the industry’s vulnerability to trade policy changes and reliance on international collaboration.

Ben Machine’s Perspective

Successful international manufacturing relationships require collaboration, trust, and strategic planning between manufacturers and suppliers across borders. Industries like aerospace rely on complex supply chains involving multiple tiers of suppliers. They thrive on effective communication, legal clarity, risk management strategies, and adaptability to global trends.

Ben Machine has the expertise and experience to navigate complex global manufacturing environments. We understand that clear communication across time zones and languages is vital to avoid misunderstandings and that regular updates and transparent processes are key to addressing issues early.

In today’s uncertain global environment, it makes even more sense for aerospace manufacturers to partner with a top-notch CNC machine shop in Ontario’s aerospace industry. Explore how Ben Machine can contribute to your next project!