As artificial intelligence continues to grow, so do the demands placed on the hardware that supports it. More powerful processors, denser chip architectures, and faster data throughput all lead to one unavoidable challenge: heat.

In sectors like aerospace, defence, and high-performance computing, managing that heat is no longer a secondary concern; it’s a defining factor in system reliability and longevity.

Today’s AI-driven systems generate far more heat than traditional electronics due to increased power densities and computational loads. Modern AI processors can draw up to 1,000 W per chip, creating intense localized heat. Entire AI racks can require up to 132 kW of cooling capacity, nearly eight times that of traditional server setups.

Addressing these thermal management challenges requires efficient heat transfer, tightly controlled interfaces, and manufacturing consistency that ensures systems perform as designed over time.

While Ben Machine does not design cooling systems itself, its role as a precision CNC machining partner directly supports the performance of those systems. Tight tolerances, consistent material properties, and aerospace-grade machining standards all contribute to efficient heat dissipation and long-term thermal reliability.

For applications in radar systems, avionics, and AI-powered hardware, machining quality directly impacts how well embedded cooling solutions function. As AI continues to evolve and integrate more deeply into mission-critical platforms, thermal management will become increasingly important.

Ben Machine is positioned to support that evolution by delivering precision-machined components that help cooling technologies do their job—reliably and repeatedly.

Why Embedded Cooling Matters for AI Systems

AI-powered devices generate substantial heat due to high computational demands and concentrated power densities. Advanced processors, GPUs, and specialized AI chips are designed to perform complex calculations at incredible speeds, but that performance comes at the cost of increased thermal output. Without effective AI cooling, systems quickly face performance throttling, instability, and premature component failure.

Embedded thermal management is essential because it removes excessive heat directly from the source, rather than relying solely on external cooling methods.

Insufficient cooling can lead to:

- Overheated components

- Reduced processing efficiency

- System crashes

- Shortened hardware lifespan

Proper cooling solutions help ensure stability, consistent performance, and reliability, especially for systems that operate continuously or under heavy loads.

Modern AI hardware takes many forms, including:

- Edge AI devices deployed in remote or mobile environments

- Onboard AI processors used in aerospace and defence platforms

- High-performance GPUs for data processing and signal analysis

- Avionics and navigation processors

- Radar and sensor fusion systems

As chip stacking and compact system designs become more common, heat has less room to dissipate naturally. Higher power density means more heat concentrated into smaller physical spaces, making embedded cooling strategies even more important.

In defence and aerospace environments, extreme operating conditions amplify AI cooling challenges, including shock, vibration, altitude changes, and wide temperature swings. Embedded thermal management solutions—supported by precision machining—help ensure AI hardware continues to operate as intended, even in the harshest conditions.

The Role of Precision Machining in Embedded Thermal Management

Precision machining plays a foundational role in the effectiveness of embedded thermal management. Ben Machine does not design these systems, but the quality of our machining directly impacts thermal dynamics, efficiency, and reliability.

Tight machining tolerances ensure proper fit, alignment, and surface contact between components. These factors are critical for effective heat transfer. Even minor inconsistencies can introduce air gaps, uneven contact surfaces, or mechanical stress—all of which increase thermal resistance and reduce cooling performance.

Aerospace-grade machining standards are essential for embedded thermal management. Components must withstand repeated heating and cooling cycles without warping, cracking, or degrading over time.

Precision machining helps ensure:

- Uniform thermal interfaces

- Predictable heat flow paths

- Stress-free assemblies

- Dimensional stability across temperature extremes

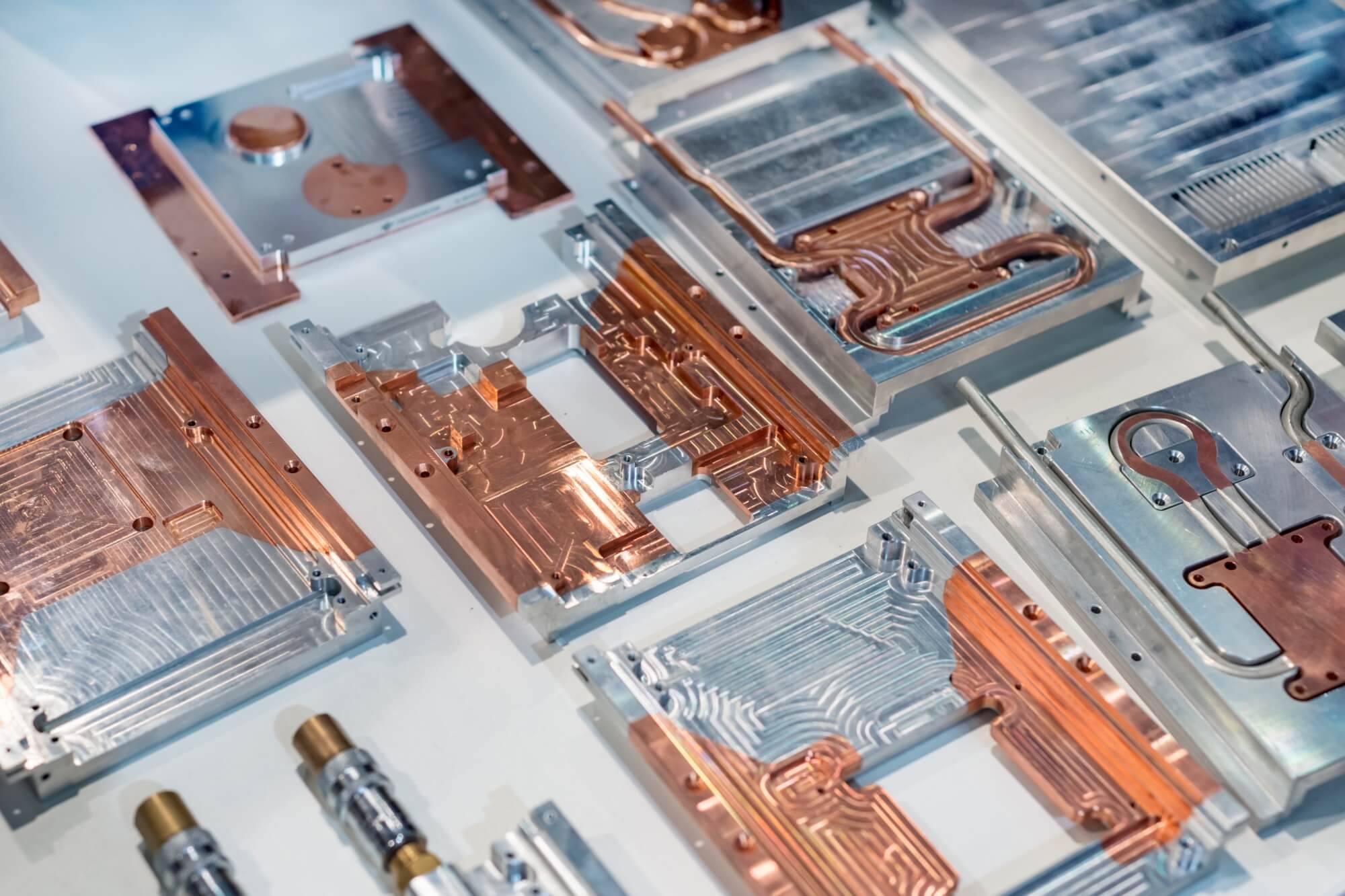

Thermal frames, housings, cold plates, and heat spreaders all rely on consistent geometry and surface quality to evenly distribute heat. Poor machining can lead to hot spots, uneven cooling, and premature failure.

Material selection also plays a significant role. Ben Machine has extensive experience working with materials commonly used in thermal applications, including:

- Aerospace-grade aluminium for its excellent thermal conductivity and low weight

- Copper for high heat transfer requirements

- Titanium, where strength, durability, and weight optimisation are critical

Optimizing strength-to-weight ratios is especially important for the aerospace industry and defence systems, where every gram matters. Precision machining allows these materials to perform as intended—balancing thermal performance, structural integrity, and weight constraints.

Advanced Cooling Technologies Supported Through Precision Machining

Ben Machine is fully conversant with advanced cooling technologies and understands how precision machining supports their effectiveness.

Heat Pipes

Heat pipes work on the principle of phase change. Heat causes a working fluid inside the pipe to evaporate, transferring thermal energy to cooler areas where it condenses and releases that heat. This process relies on consistent internal geometries and precise interfaces to ensure uniform temperature distribution and efficient heat transfer.

Vacuum Brazing

Vacuum brazing is another critical process used in advanced thermal assemblies. It joins metals under vacuum using a filler material, creating strong, clean joints with minimal thermal resistance.

This technique is commonly used to produce high-quality heat exchangers, cold plates, and complex thermal assemblies. Precision machining before brazing is essential; poorly machined surfaces can lead to weak joints, misalignment, or uneven thermal paths.

Heat Fins

Heat fins are also widely used to increase surface area for thermal exchange, improving convection and radiation heat dissipation. Machining consistency ensures fins are uniform, properly spaced, and structurally sound

Beyond these established methods, embedded thermal management increasingly relies on:

- Embedded cold plates with internal flow channels

- Micro-machined fins for high surface-area density

- Liquid cooling integration for high-power systems

Precision machining is critical for controlling coolant pathways, maintaining consistent wall thicknesses, and reducing thermal resistance. Even minor deviations can disrupt fluid flow or reduce heat transfer efficiency. In contrast, properly machined components help ensure uniform heat spread and predictable cooling performance.

What Role Does Ben Machine Play in Keeping These Systems Cool?

Ben Machine’s role in embedded thermal management is rooted in manufacturing excellence. We machine complex geometries with tight tolerances, allowing cooling systems to perform as designed—especially in demanding aerospace and defence applications.

Many thermal components require intricate internal features, thin-walled structures, and precise mating surfaces. We produce these features without introducing stress, distortion, or dimensional variability that could compromise thermal performance.

Our expertise extends beyond machining alone. Ben Machine supports advanced finishing, brazing, and assembly processes commonly required in defence-grade thermal components. This integrated approach helps ensure that parts meet both thermal and structural requirements.

Our high-mix, low-volume production model is particularly valuable for:

- Prototypes and early-stage development

- Rapid design iterations

- Low-volume, high-complexity programs

- Long-term production with consistent quality

Examples of components we support include:

- Thermal frames for onboard AI computing systems

- Radar cooling housings

- Avionics processor heat sinks

- Defence sensor cold plates

With quality systems aligned with aerospace standards such as AS9100, Ben Machine maintains tight tolerances even under demanding delivery schedules.

Applicability Across High-Demand Sectors

Keeping systems cool is essential across many high-demand sectors, particularly in defence and aerospace. From robust radar systems to advanced avionics and directed energy platforms, modern defence equipment generates significant heat. When thermal management fails, system performance and reliability suffer.

Embedded thermal management ensures sensitive electronics continue to function despite:

- Extreme temperatures

- Shock and vibration

- Rapid heating and cooling cycles

- Altitude and pressure changes

Studies show that up to 55% of electronic component failures in aerospace systems are linked to temperature stresses, emphasizing the importance of embedded thermal management and aerospace-grade machining in maintaining reliability under harsh conditions.

CNC machining plays a significant role in thermal management by enabling the production of complex components such as heat sinks, heat pipes, and cold plates. Materials like titanium, high-grade aluminium, and copper are commonly used because they can withstand thermal stress while efficiently transferring heat. Precision machining ensures these materials perform as intended, especially in flight-critical hardware where weight and strength-to-weight ratios matter.

Ben Machine also supports advanced assembly, brazing, and finishing processes, providing complete, production-ready thermal components that meet demanding aerospace and defence requirements.

Engineering Expertise That Brings Thermal Designs to Life

Effective thermal solutions require more than good design—they must also be manufacturable. Custom embedded cooling solutions rely on a strong understanding of thermodynamics, materials science, and engineering principles.

Simulation tools, such as Computational Fluid Dynamics (CFD), predict heat flow and distribution, informing design decisions that balance thermal performance, size, weight, and cost. Ben Machine collaborates closely with engineers from the earliest stages, ensuring components can be machined accurately without compromising thermal intent.

Prototyping and iterative improvements allow designs to be tested, refined, and optimized before full production. Throughout this process, long-term reliability is a priority—especially for systems exposed to repeated thermal cycling.

The Future of Embedded Thermal Management in AI and Aerospace

AI integration in aerospace and defence is accelerating. In fact, the AI aerospace & defence market — valued at roughly US$26.6 billion in 2024 — is projected to reach over US$44 billion by 2030, with long‑term forecasts exceeding US$65 billion by 2034, reflecting steady double‑digit growth as systems become smarter and more capable.

From autonomous systems and drones to advanced surveillance platforms and edge computing, embedded AI is becoming standard across mission-critical applications. As these systems grow more powerful, thermal demands will continue to increase.

Higher power densities, compact system architectures, and new materials will push embedded thermal management requirements even further. Cooling solutions will need to be more efficient, more integrated, and more reliable than ever before.

At the same time, manufacturing methods are evolving. Precision machining, advanced materials, and integrated assembly processes will play an even larger role in supporting next-generation thermal designs.

Ben Machine is well-positioned to support this future. Their adaptability, precision machining expertise, and experience in high-mix, low-volume production enable them to keep pace with emerging technologies. As AI continues to reshape aerospace and defence systems, Ben Machine remains ready to support the thermal performance on which those systems depend.

Conclusion

Embedded cooling and thermal management are no longer optional features—they are essential to the performance, reliability, and longevity of AI-powered and aerospace systems. As heat loads increase and operating environments become more demanding, precision manufacturing is critical to ensuring that cooling technologies perform as intended.

Ben Machine’s precision CNC machining capabilities directly support embedded thermal management. Tight tolerances, aerospace-grade standards, and expertise with advanced materials help ensure components withstand repeated thermal cycles without warping, cracking, or failure.

As AI integration in defence and aerospace continues to grow, thermal management will only become more critical. Ben Machine is prepared to keep pace with that innovation, supporting customers with reliable, precision-machined components that enable effective AI cooling and long-term system performance.

If you’re developing advanced systems where thermal performance matters, Ben Machine is ready to support your next challenge.