A cleanroom is a super-sanitized space designed to keep contamination at bay by reducing particles, bacteria, and pollutants to an absolute minimum. Sticking to strict cleaning rules in these environments is non-negotiable.

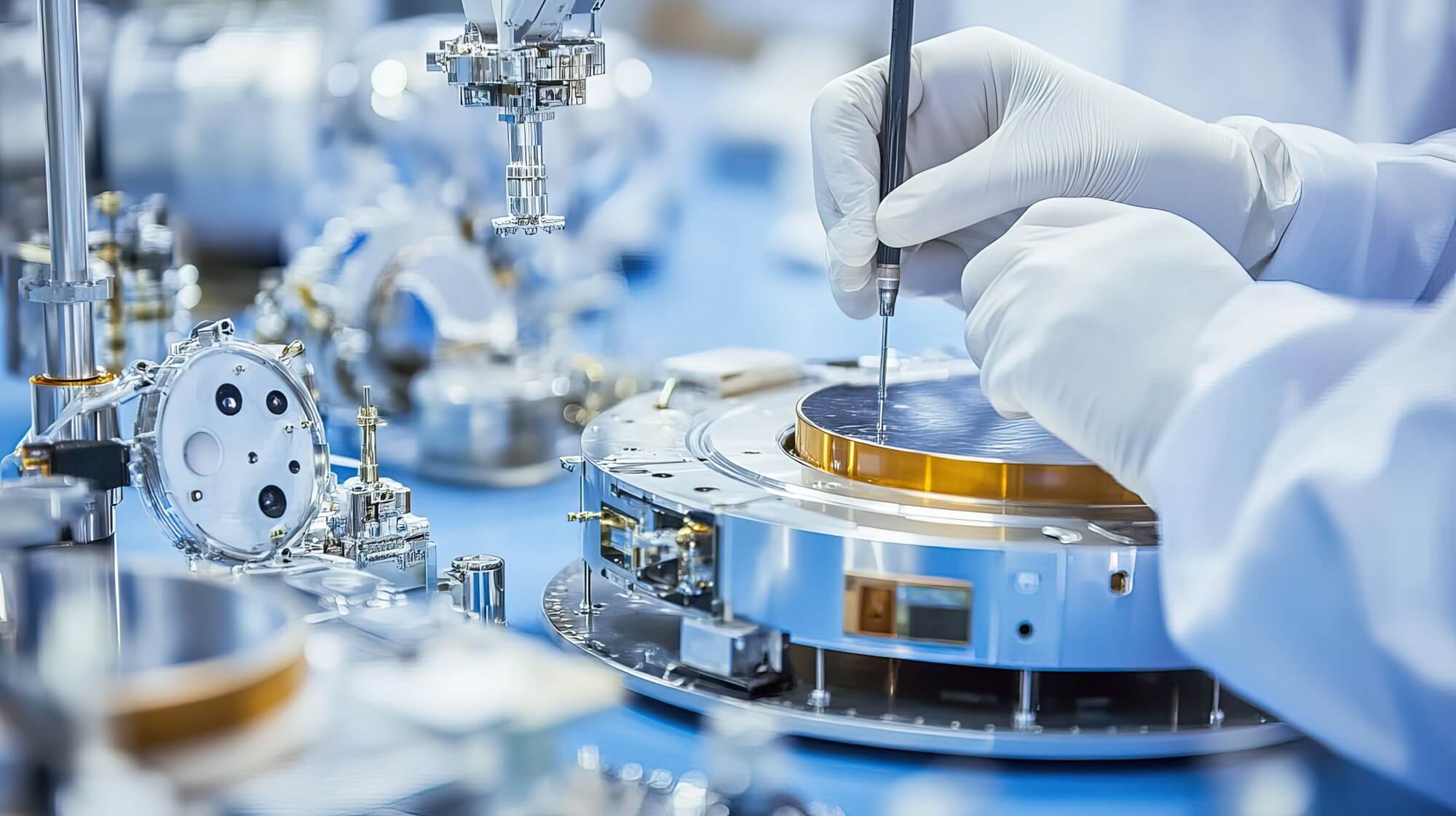

For industries like aerospace and defence, where even the tiniest particle can jeopardize the reliability of a finished product, cleanroom assembly plays a crucial role. By combining advanced environmental controls with precision machining expertise, companies can achieve contamination-free production that supports the most demanding applications.

At Ben Machine, our ISO 7 cleanroom (also meeting ISO 8 requirements) has been purpose-built for precisely this type of work. Equipped with advanced monitoring, electrostatic discharge (ESD) protection, and tightly controlled temperature and humidity systems, our cleanroom supports high-stakes assemblies where precision and quality are non-negotiable.

The Importance of Cleanroom Assembly in CNC Manufacturing

Cleanrooms are crucial for higher-level assemblies in the aerospace and technology sectors. These industries often work with components that will eventually function in high-stakes environments, where the margin for error is razor-thin.

Take aerospace, for example. Satellite systems, navigation instruments, and space exploration hardware all rely on precision manufacturing cleanrooms to ensure that assemblies are free from dust or microscopic contaminants. A single speck of dust can compromise a sensor, throw off an optical system, or weaken the long-term reliability of a component meant to last years in orbit.

Defence applications also demand this level of precision. Advanced targeting systems, communications equipment, and electronic assemblies must work flawlessly in the field. Contaminants that interfere with soldering, bonding, or electrical conductivity could result in costly malfunctions or safety risks.

Ben Machine’s cleanroom meets these challenges head-on. With ISO 7 certification, continuous monitoring, and advanced environmental controls, it provides the optimal environment for sensitive assemblies. By integrating cleanroom assembly directly with in-house CNC machining, we reduce risk, streamline workflows, and maintain tight quality standards—helping customers build with confidence.

Advanced Cleanroom Technologies in CNC Manufacturing

Sophisticated cleanroom setups that support precision CNC manufacturing and complex assembly incorporate several unique features that are vital for maintaining the highest standards of cleanliness and control. At Ben Machine, our cleanroom is more than a controlled space; it’s a complete system designed to deliver consistent, contamination-free results for sensitive assemblies.

Air Handling and Filtration

Air purity is at the core of every cleanroom. Ben Machine’s facility uses HEPA filtration with up to 60 air changes per hour, constantly flushing the space with clean, particle-free air. Positive air pressure is maintained at all times, which means if a door opens, clean air flows outward—keeping contaminants from entering.

In addition, our systems are equipped with real-time monitoring and alarms, ensuring that differential pressure and filtration performance are continuously verified. This creates a stable environment to build sensitive assemblies without compromise.

Environmental Controls

Maintaining consistent conditions is just as important as filtering the air. Ben Machine’s cleanroom features tightly controlled temperature and humidity regulation, which prevents material warping, ensures adhesive stability, and keeps ESD risks under control. These environmental controls are critical when working with materials for aerospace or defence, where dimensional stability is essential.

Real-Time Monitoring and Alarms

Our cleanroom is constantly monitored, with sensors measuring temperature, humidity, pressure, and particle counts. If levels deviate from acceptable ranges, alarm systems immediately alert staff, allowing them to make corrections before the processes are affected. This proactive monitoring helps guarantee that every assembly meets the required standard.

ESD Protection

Static discharge may seem minor, but in advanced assemblies it can destroy delicate electronic components. That’s why our cleanroom includes a complete ESD-protection system, including grounded workbenches and continuous wrist strap monitoring. Every operator working on electrostatic discharge-sensitive (ESDS) assemblies is protected, ensuring both employee safety and product integrity.

By combining these technologies, Ben Machine has created a state-of-the-art precision manufacturing cleanroom certified to ISO 14644. This facility enables us to take on projects that demand not only precision machining but also contamination-free assembly—including high-profile aerospace initiatives like the Lunar Gateway project.

ISO 7 vs. ISO 8 Cleanrooms: What’s the Difference?

When discussing cleanrooms, the ISO classification system plays a crucial role. The classification defines the number of particles allowed per cubic metre of air, with stricter classes permitting fewer contaminants.

- ISO 8 cleanrooms are most common in manufacturing, including aerospace and defence. They allow up to 3,520,000 particles ≥0.5 µm per cubic metre. For many industries, this is sufficient for assembly and inspection.

- ISO 7 cleanrooms, by comparison, permit only 352,000 particles ≥0.5 µm per cubic metre—a tenfold improvement in cleanliness. This tighter control makes ISO 7 ideal for industries where contamination can have critical consequences.

Ben Machine’s cleanroom is ISO Class 7 certified, and it also exceeds the requirements by meeting ISO Class 8 standards. This distinction matters: while many machine shops offer ISO 8 cleanrooms, our ISO 7 environment represents a higher level of control and capability. For customers, it means greater confidence that assemblies will meet the rigorous demands of mission-critical projects.

Cleanroom Assembly Services at Ben Machine

Our cleanroom isn’t just about maintaining a controlled environment—it’s about delivering specialized assembly services that support complex, high-value projects.

Ben Machine provides cleanroom assembly for both mechanical and electro-mechanical systems, with a focus on industries where failure is not an option. This includes aerospace components destined for orbit, advanced defence electronics, and high-reliability assemblies.

What sets us apart is the integration of cleanroom assembly with our in-house CNC machining operations. By keeping production and assembly under one roof, we can:

- Ensure consistent quality from raw material through final assembly

- Eliminate the risks of contamination that come with shipping parts between facilities

- Shorten lead times by streamlining the production process

- Provide turnkey solutions where customers receive a complete, fully assembled product

We have already applied this integrated approach to projects like components for the Lunar Gateway, where space-grade requirements demand both machining precision and contamination-free assembly. For customers, it means fewer headaches, minimized risk, and the confidence that we are handling their most sensitive projects to the highest standards.

Regulatory Compliance and Industry Standards

Cleanrooms are not just about cleanliness—they’re about compliance. Many industries require adherence to strict standards to ensure that assemblies are safe, reliable, and ready for use in critical applications.

At Ben Machine, our cleanroom is ISO 14644 certified, which verifies the level of air cleanliness and environmental control. We also apply standards like ASTM A967 for passivation and maintain procedures that align with aerospace and defence requirements.

Adherence to rigorous standards like these significantly elevates precision manufacturing capabilities by:

- Ensuring controlled environments that minimize contamination

- Enhancing the reliability and consistency of finished assemblies

- Demonstrating a commitment to quality and safety for regulated industries

- Opening doors to new opportunities in aerospace and defence

For customers, this compliance provides peace of mind. It demonstrates that assemblies manufactured at Ben Machine are not only built to exacting standards but also certified to meet the requirements of some of the world’s most highly regulated industries.

Conclusion

Cleanroom assembly is more than a technical requirement—it’s the foundation for building reliable, high-performance systems in industries where failure is not an option. By investing in advanced cleanroom technologies and protocols, manufacturers can maintain contamination-free environments that protect both product quality and the safety of the end-user.

Ben Machine’s ISO 7 cleanroom represents a significant step forward in precision manufacturing. From HEPA-filtered air exchanges and continuous environmental monitoring to ESD protections and turnkey assembly integration, our facility supports the most ambitious projects in aerospace and defence technology.

Continuous innovation in cleanroom practices is crucial for CNC manufacturing and complex assembly, as it ensures stringent control over contamination, enhances product precision, and maintains competitiveness in demanding markets.

To learn more about how our cleanroom capabilities can support your next project, contact Ben Machine today to schedule a technical consultation.