CNC prototyping plays a vital role in the defence sector by enabling precise and rapid development of complex parts. CNC machining offers an opportunity to produce complex prototype components to the highest standards of accuracy and quality, ultimately leading to advanced defence solutions capable of meeting stringent military requirements.

CNC Machining’s Role in Defence Innovation

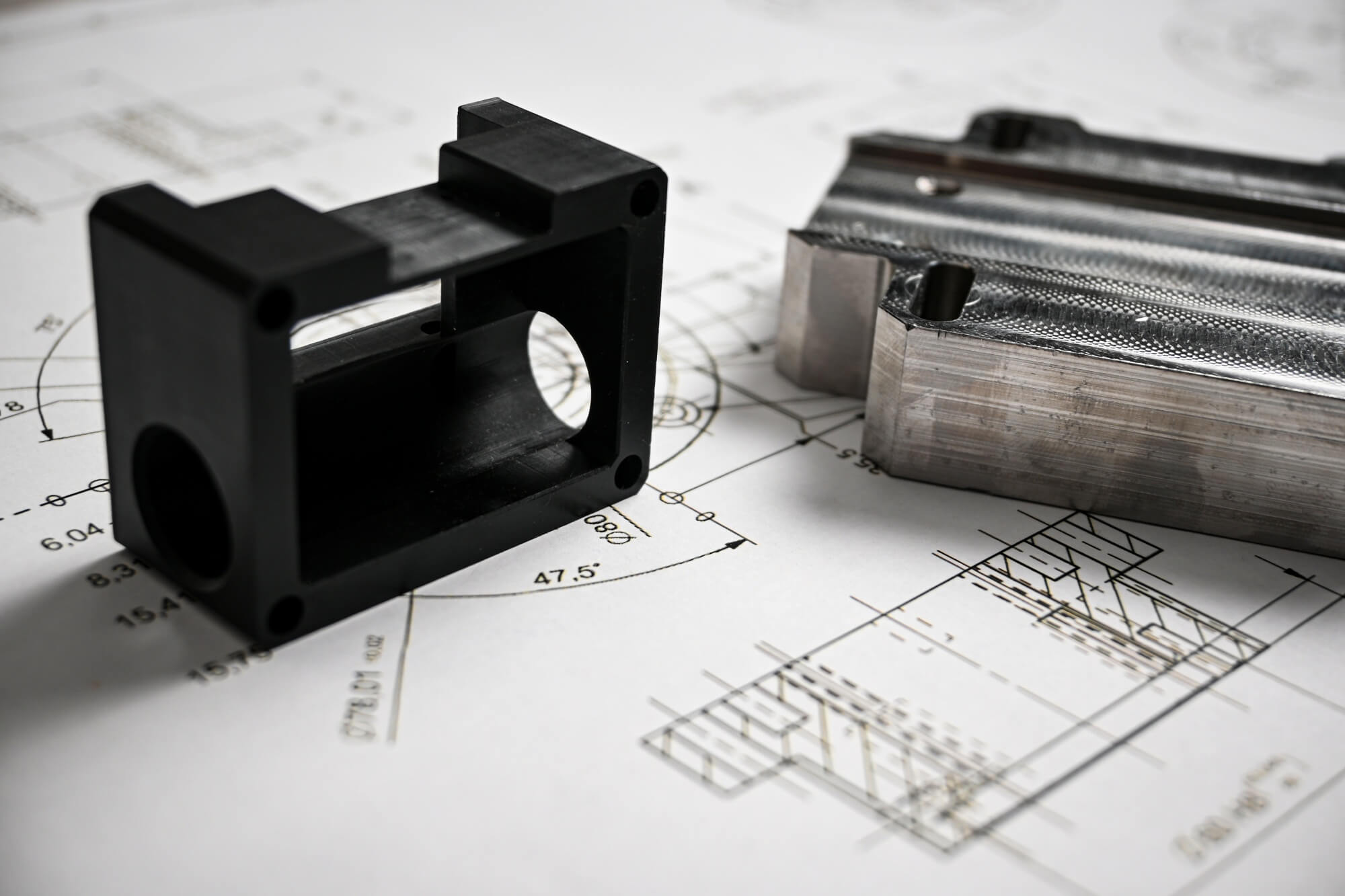

CNC machining is well-suited for rapid prototyping, with its ability to quickly modify designs and produce parts with precise tolerances, which is essential for demonstrating new technologies and concepts. Every major defence innovation, whether in weapons systems, vehicles, electronics, or other military equipment, relies heavily on CNC prototyping capabilities.

Combining CNC machining and high-quality prototyping enables the defence industry to innovate rapidly and adapt to evolving technological and material requirements, ensuring that defence systems remain effective and competitive.

Case Study: Aerospace Tech Adaptation for Land Vehicles

To illustrate the practical application of CNC prototyping in defence, let’s examine a case study that highlights how precision machining can solve complex challenges.

An aerospace systems supplier faced cost efficiency challenges due to complex aerodynamic designs. They partnered with Ben Machine to leverage our precision prototyping and machining capabilities, developing a cost-effective solution tailored for terrestrial applications and scalable for mass production.

Our collaborative approach with the client’s design team focused on prototyping a series of iterative adjustments to streamline the original aerodynamic features. Through rapid prototyping, we removed unnecessary airborne capabilities and fine-tuned the design, resulting in a durable, cost-effective solution for land vehicles without compromising quality.

This partnership highlights Ben Machine’s innovation and flexibility in CNC prototyping, demonstrating our ability to transform complex aerospace designs into practical, market-ready systems. By bridging aerospace technology with land vehicle applications, we set a new standard in engineering problem-solving and prototyping excellence.

Speed and Precision: The Backbone of Defence Prototyping

Precision CNC machining ensures that parts meet strict specifications and perform reliably under extreme conditions. This precision is crucial for maintaining the safety and effectiveness of defence systems.

In addition, CNC machining works with a wide range of materials, from lightweight plastics to high-strength metals, allowing for creating diverse components such as aircraft parts and military vehicle components.

Although CNC machining supports small-scale prototyping and large-scale production, ensuring consistent quality across all components, its prototyping enables the quick creation and testing of parts and systems, allowing engineers to refine designs rapidly and accelerate the development process.

Prototyping significantly reduces the time from design to deployment, which is critical in scenarios where timing can influence national security.

By identifying and addressing issues early in the development phase, prototyping minimizes costly revisions later, making it a cost-efficient strategy.

CNC machining works well for rapid prototyping because it allows engineers to quickly modify designs and produce parts with tight tolerances, essential for demonstrating new technologies and concepts.

CNC machining and prototyping are integral to the defence industry’s ability to quickly innovate and develop new technologies. They provide the precision, efficiency, and adaptability needed to meet the industry’s stringent requirements and keep pace with evolving threats and technologies.

Ben Machine’s Expertise and Contribution to Defence Innovation

With decades of expertise, Ben Machine is one of Canada’s most trusted and capable CNC machining companies. Equipped with over 60 state-of-the-art CNC centers at our main facility and more than 100 across our divisions, we deliver unmatched precision and capability.

We have partnered with military, defence, and homeland security companies and fully comply with Canadian and US defence regulations. Our defence machining experience and capabilities respond to various military component manufacturing needs.

Our advanced machining technology supports the demanding needs of the aerospace, military, and other industries. Anyone within these industries and beyond will benefit from talking to our experts in CNC prototyping services.