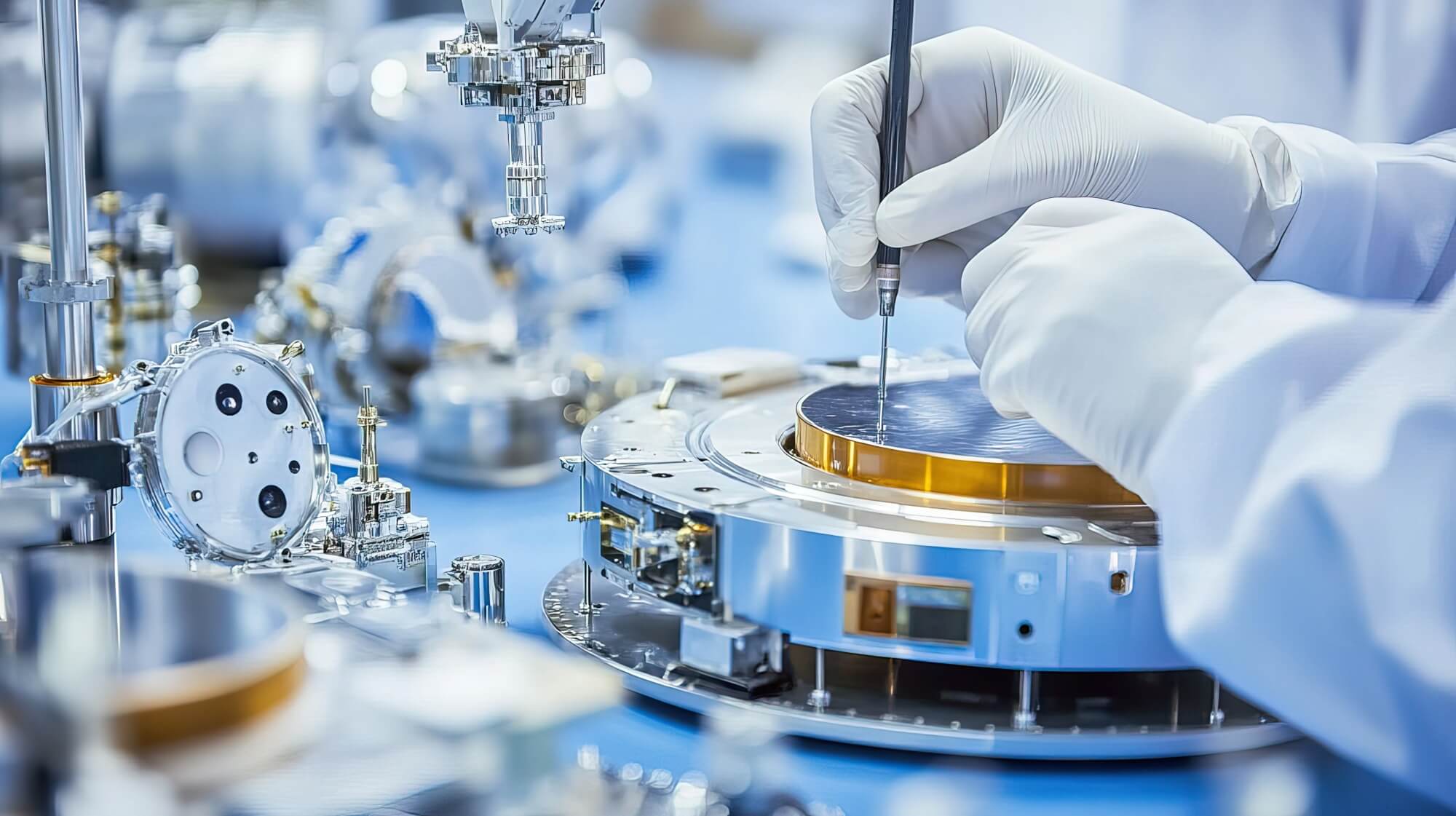

Cleanroom for Precision Assembly

Why Use a Cleanroom?

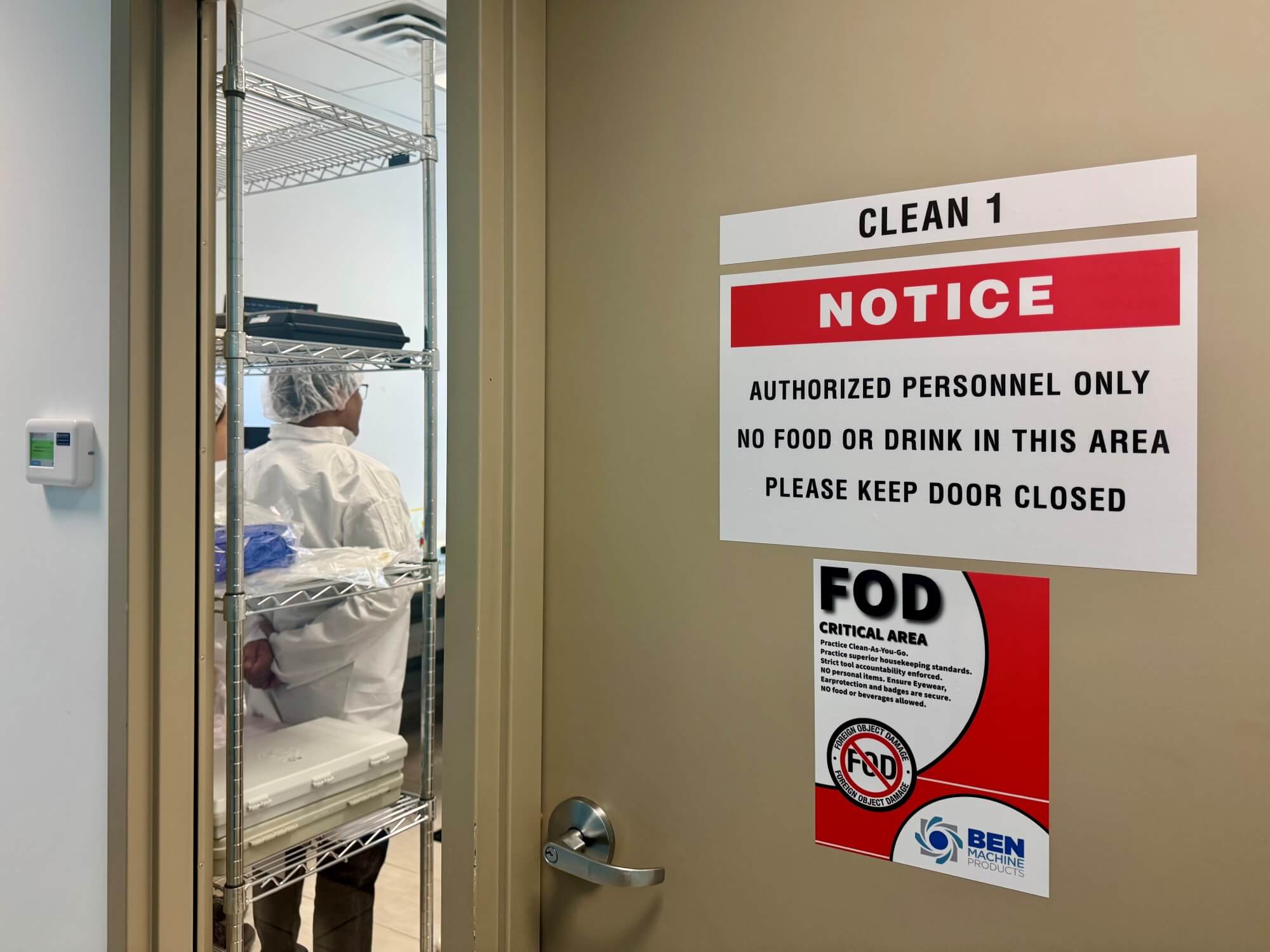

Ben Machine’s ISO Class 7 cleanroom, which therefore meets ISO Class 8 requirements, is a controlled environment where airborne particles, contaminants, and environmental conditions (such as temperature, humidity, and pressure) are tightly regulated.

A cleanroom is essential for building assemblies using high-precision aerospace and defence components, where even a small contamination can compromise functionality, reliability, or compliance with regulatory standards. By eliminating environmental variables, assemblies built in a cleanroom ensure optimal performance, reduce the risk of product failure, and support long-term durability in mission-critical applications.

Our Clean Room Capabilities

Ben Machine’s cleanroom is engineered to support the precise and contamination-free assembly of sensitive mechanical, optical and electro-mechanical components. Our cleanroom services are purpose-built for high-reliability applications, combining advanced environmental controls with integrated manufacturing support to help customers build a product with confidence.Cleanroom Environment

- ISO 14644 certified, ISO Class 7 (therefore meeting ISO Class 8 requirements)

- Up to 60 HEPA-filtered air exchanges per hour

- Positive-pressure environment to keep contaminants out

- Continuous temperature and humidity control to ensure material stability

- Real-time monitoring and alarms for differential pressure and HEPA filter performance

- Particle count performance:

- ≤ 352,000 at 0.5 µm

- ≤ 2,930 at 5 µm

ESD Protection & Assembly Controls

Our ESD control systems ensure a high level of protection for sensitive components through the following measures:- Grounded workbenches to prevent electrostatic discharge

- Continuous wrist strap monitoring for operator safety and component integrity

- Designed for Electrostatic Discharge Sensitive (ESDS) assembly tasks

Integrated Turnkey Manufacturing

- Supports complex mechanical, optical and electro-mechanical assemblies

- Integrated with in-house CNC machining for high-precision part fabrication

- Ideal for space-grade projects such as Lunar Gateway and other mission-critical applications

By combining cleanroom assembly with our end-to-end production capabilities, Ben Machine ensures streamlined workflows, minimized risk, and consistent quality for demanding industries such as aerospace and defence.

Quality and Compliance

Ben Machine’s cleanroom is audit-verified to ISO 14644, ensuring consistent conformance to strict cleanliness standards. We safeguard quality through an integrated alarm system that instantly alerts operators to pressure deviations or HEPA filtration failures. Environmental conditions (including particle counts, humidity, and temperature) can be continuously monitored, with detailed logs available upon customer request for complete traceability.

These controls ensure the cleanroom’s performance is not only certified but also actively maintained and verified. This rigorous approach guarantees that we complete every mechanical, optical and electro-mechanical assembly in an environment that meets or exceeds the quality expectations of the most demanding industries.

Industries Served

We proudly support industries where precision and reliability are critical. Our cleanroom assembly services meet the stringent demands of:

Precision assemblies for mission-critical operations

High-reliability components for advanced systems

Space-grade assemblies for demanding environments

Services We Provide

Ben Machine delivers turnkey precision cleanroom assembly services built for critical applications, meeting the demands of aerospace and defence with precision and reliability.

Our ISO Class 7 cleanroom supports:

- Aerospace and defence component assemblies– Assembled in a contamination-controlled environment for maximum reliability

- CNC-machined part assembly and kitting –Integrated with in-house machining for streamlined delivery and quality control

- Testing – Specification-driven validation processes to ensure functional and mechanical integrity

- Inspection – Detailed inspections to confirm compliance with the most demanding industry standards

Every project benefits from our skilled technicians, diligent testing and inspection processes, ensuring compliance with the most demanding specifications. Operating in a cleanroom-certified environment, we maintain the highest levels of quality control for sensitive, mission-critical builds.

From prototype to full production, our integrated capabilities ensure performance, consistency, and reliability in even the most challenging applications.

Why Choose Us?

Ben Machine offers one-stop capabilities, combining precision CNC machining with mechanical and electro-mechanical assembly in our ISO Class 7 cleanroom. By managing every stage in-house, we work closely with customers to meet all requirements, reducing supply-chain complexity, mitigating risk, and ensuring consistent quality.

Our integrated approach delivers cost savings, faster turnaround, and seamless transition from rapid prototypes to full-scale production. With expertise in mission-critical aerospace and defence projects, we provide the precision, reliability, and flexibility needed for high-stakes applications.

Partner with a team that delivers proven results in the most demanding environments. Speak with the experts at Ben Machine to discuss your project today.

Let us strengthen your position in the military, defence and homeland security industry.

FAQs

Ben Machine operates an ISO 7 cleanroom ( therefore meeting ISO Class 8 cleanroom requirements) certified to ISO 14644 standards. It features ESD controls, up to 60 HEPA-filtered air exchanges per hour, continuous positive pressure, temperature and humidity control, and real-time environmental monitoring.

Our cleanroom is ISO Class 7 and supports a wide range of precision mechanical and electro-mechanical assemblies—including space-grade, aerospace, and defence components. If your product requires strict contamination control, ESD-safe handling, or clean assembly conditions, it’s likely a strong fit. We also provide detailed environmental monitoring logs upon request and are happy to review your specifications to confirm compatibility.

We work closely with our customers to define specifications and develop detailed procedures that align with drawing and documentation requirements. Within our certified cleanroom, we perform precision assembly, as well as any required testing and inspections, followed by packaging — all carried out in strict accordance with customer requirements.

Positive-pressure airflow, HEPA filtration, environmental controls, gowning protocols, and continuous monitoring of HEPA filters maintain cleanliness. Any deviations trigger real-time alarms, alerting operators immediately so corrective action can be taken before product quality or compliance is compromised.

Only trained, authorized personnel who follow strict gowning and handling procedures are allowed. All visitors must be accompanied by authorized personnel.

Yes. We integrate high-precision CNC machining with cleanroom assembly capabilities for complete turnkey solutions.