A shift is occurring in CNC manufacturing processes. Versatile high-mix, low-volume (HMLV) production is moving to replace some of the large-scale repetitive product processes. Flexibility is essential because of the diversity of parts, smaller batch sizes, and frequent changeovers with HMLV.

The good news? Modern automation solutions are built with these complexities in mind. They deliver flexible, efficient systems that boost productivity without sacrificing the adaptability your shop depends on. At Ben Machine, we adopt automation tailored to our customer’s unique production requirements.

Rethinking Automation for Precision CNC Machining

Traditional automation in the context of high-mix, low-volume (HMLV) CNC machining jobs faces several limitations, primarily due to the need for flexibility and adaptability in these environments.

Traditional automation systems are often designed for repetitive tasks and are less adaptable to frequent product type or configuration changes. This rigidity can hinder efficient production in HMLV environments, where the product mix is diverse and batch sizes are small. Traditional automation typically involves longer setup times for each new product, significantly reducing productivity in HMLV settings where frequent changeovers are necessary.

HMLV manufacturing can involve volatile and unpredictable demand, which traditional automation systems may struggle to accommodate due to their lack of flexibility and adaptability.

To overcome these limitations, manufacturers are turning to more flexible automation solutions, such as cobots, modular automation systems, and advanced CNC machining techniques that allow for quick tool changes and real-time adjustments.

Flexibility and Integration in Manufacturing Automation

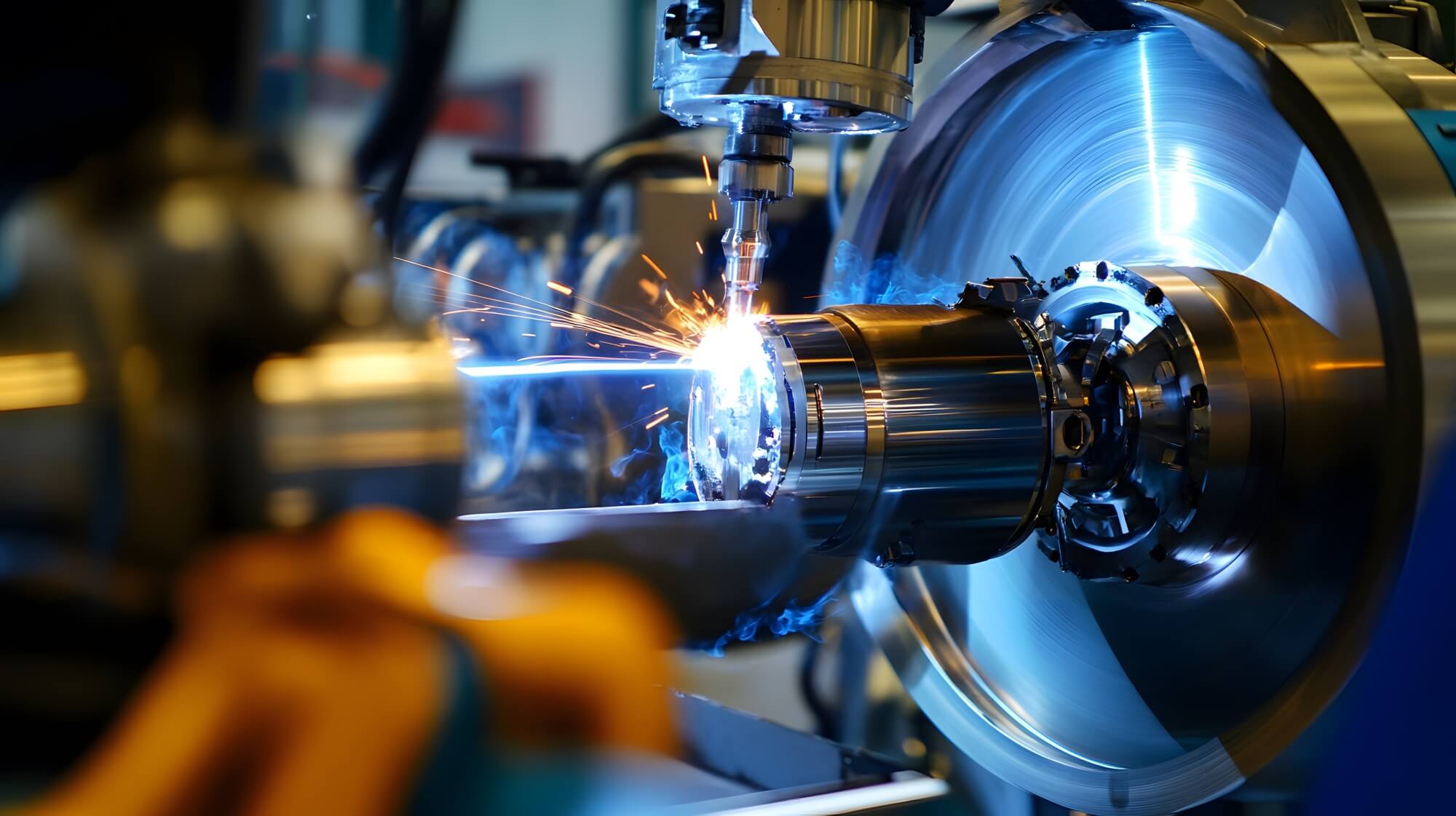

Ben Machine stays ahead by adopting the latest advancements that directly enhance HMLV (high-mix, low-volume) manufacturing and meet the needs of precision engineers. Our 5-axis machine tools enable simultaneous machining, where both the part and cutting tool move in sync, significantly reducing machining time and increasing efficiency.

We refine our processes by integrating innovations such as advanced workholding technologies, simulation techniques, high-speed spindles, and lean manufacturing principles. These advancements deliver strategic benefits tailored explicitly for precision-driven industries like defence, aerospace, and other sectors requiring exacting engineering and HMLV manufacturing solutions.

Enhancing CNC Workflows with AI-Assisted Programming

Integrating robotics and artificial intelligence (AI) in CNC machining offers numerous benefits to transform manufacturing by enhancing efficiency, precision, and productivity.

- Advanced AI algorithms analyze data from past projects and predict optimal toolpaths, reducing programming time while improving output accuracy.

- AI continuously scrutinizes operations and draws from extensive data sets, offering real-time, detailed reports that enable manufacturers to make informed decisions quickly.

- Finally, consider the machine setup—a crucial step that dictates the workflow. With precision and consistency, robots can ensure that setups are exact, replicating conditions seamlessly across different production runs.

Custom Automation: The Key to Small-Batch Excellence

For shop owners managing HMLV production, automating processes can feel like a tough challenge. With a wide variety of parts, smaller batch sizes, and frequent tool changes, it’s easy to think automation isn’t a fit. However, modern automation solutions can be built specifically with these needs in mind.

Among the benefits of implementing automated systems in HMLV manufacturing are the following:

- Improved consistency

- Reduced setup times

- Optimized skilled labor

- More production hours

- Enhanced quality control

Wrapping Up

Precision automation technology in HMLV CNC machining offers several benefits, including enhanced flexibility, increased efficiency, better consistency, and improved quality.

Ben Machine continues to explore innovative ways to enhance its operations and meet the demands of its diverse customer base. By adopting customized automation systems that align with the specific needs of HMLV production, Ben Machine is positioning itself for future growth, ensuring that it can efficiently handle smaller batch sizes, frequent changeovers, and a wide variety of parts without sacrificing the precision and quality that customers expect.

As the industry evolves, Ben Machine remains committed to staying at the forefront of technology, integrating cutting-edge solutions that further elevate its manufacturing capabilities.