At Ben Machine, we prioritize design for manufacturability (DFM) to optimize product design, making machining easier, more efficient, and more cost-effective, while maintaining functionality and quality.

But what is DFM?

DFM is aligning engineering and production, especially during the design phase, to optimize every manufacturing aspect from start to finish and reduce effort and costs by simplifying the CNC machining process.

Ben Machine’s DFM Expertise in CNC Machining

Ben Machine’s product design team collaborates with our customers’ mechanical engineers to help them develop their parts. During our discussions, we gather valuable “design for manufacturability” inputs and review design intents to help identify errors and/or unnecessary requirements, resulting in a robust strategy for our high precision, tight tolerance work.

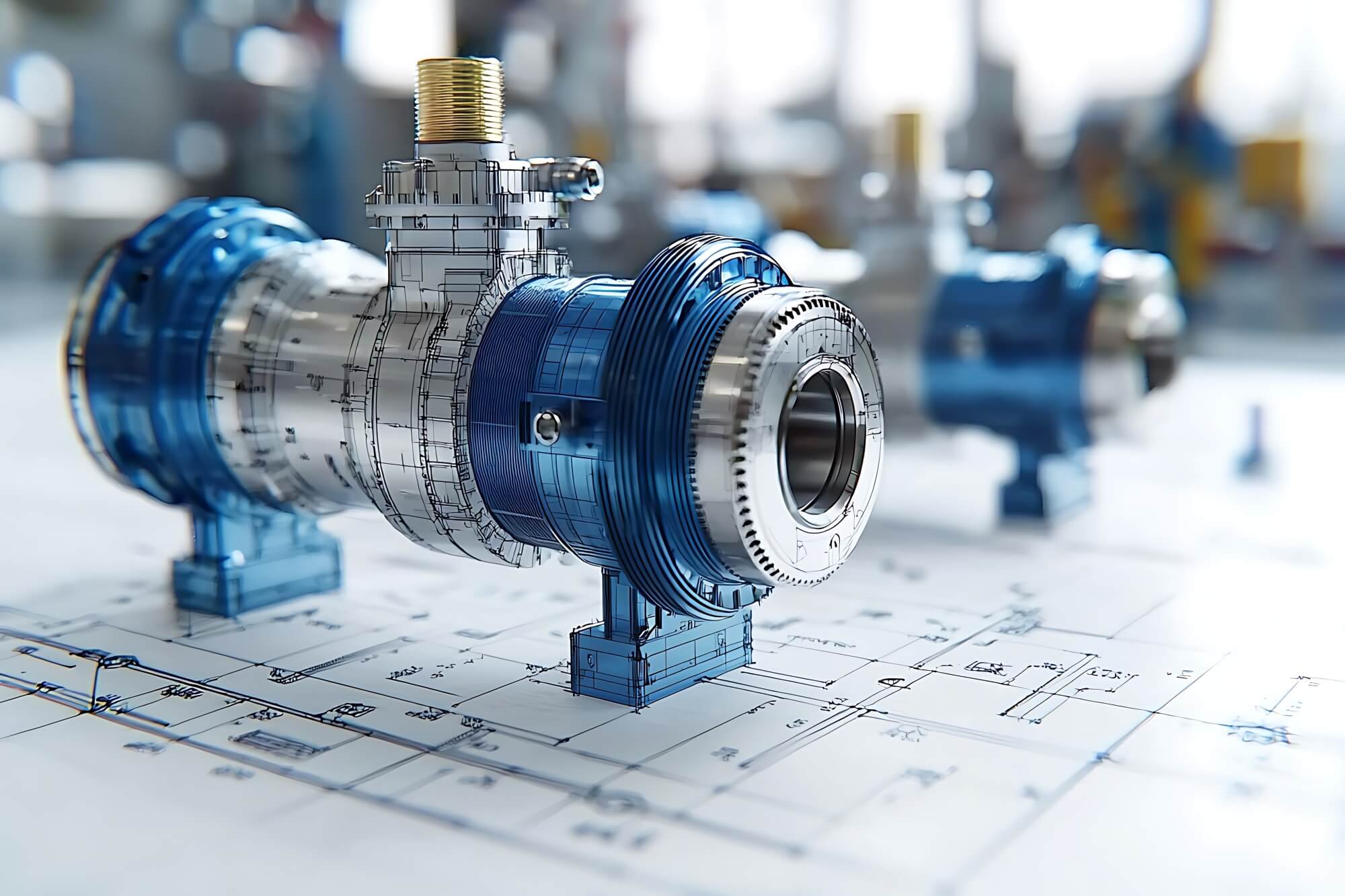

Integrating computer-aided design (CAD) with computer-aided manufacturing (CAM) software is a cornerstone of our manufacturing process. This integration enables the efficient translation of CAD designs into executable CNC programs, streamlining the path from design to production.

The benefits of CAD-CNC integration lead to reduced production lead times, enhanced quality of the machined part, and improved overall operational efficiency.

Case Study: Solving an Engineering Challenge on the F-35

Our customer leveraged Ben Machine’s manufacturing design capabilities to help develop new electronic power and control modules for the F-35 combat aircraft’s advanced actuation systems.

Our designers added advanced fixturing techniques, structural supports, and design elements to the actuator assembly to maintain dimensions and tolerances that were otherwise unachievable.

The starting point in this engineering journey was creating initial designs in virtual 3D CAD to confirm manufacturability, which moved this engineering challenge into the first iteration of a real working product.

Holistic DFM in CNC Machining

DFM addresses several common challenges impacting production efficiency, quality, and cost. Some of those include:

- Complex geometries may not be accessible for cutting tools. DFM ensures complex features are feasible and optimized for CNC machining.

- Thin walls can lead to deformation during CNC machining operations. DFM suggests adjusting cutting parameters and reinforcing wall thickness to prevent this.

- Deep pockets and holes can be an issue because of tool length limitations and chip evacuation problems. DFM advises designing holes with depths not exceeding 6 times their diameter and optimizing tool paths for efficient material removal.

- Square corners and sharp edges in part design can be costly and difficult to machine. DFM principles recommend using fillets or chamfers to improve CNC machining operations.

Get a Competitive Edge in CNC Machining with Ben Machine

Ben Machine’s DFM services provide clients with a competitive edge in CNC machining. Our DFM can be the primary factor for efficiency and innovation in CNC-manufactured products, helping to avoid special tools for overly complex manufacturing processes and reducing lead times.

Our commitment to DFM aligns with our mission of delivering leading-edge CNC machining solutions. Talk to the CNC professionals at Ben Machine for expert DFM services that optimize your CNC machining requirements.