CNC machining enables shops to produce complex, precision components within tight tolerances. Because of their precision, efficiency, and versatility, these parts are essential for Canada’s high-performance defence applications. The technology supports rapid prototyping and scalable production, ensuring timely delivery while maintaining stringent quality and security standards. These capabilities are vital in the manufacturing of mission-critical components that will ultimately perform in high-stakes environments.

From the design phase to deployment, Ben Machine ensures the integrity and precision of these essential military components, maintaining a steadfast commitment to quality at every step of the process.

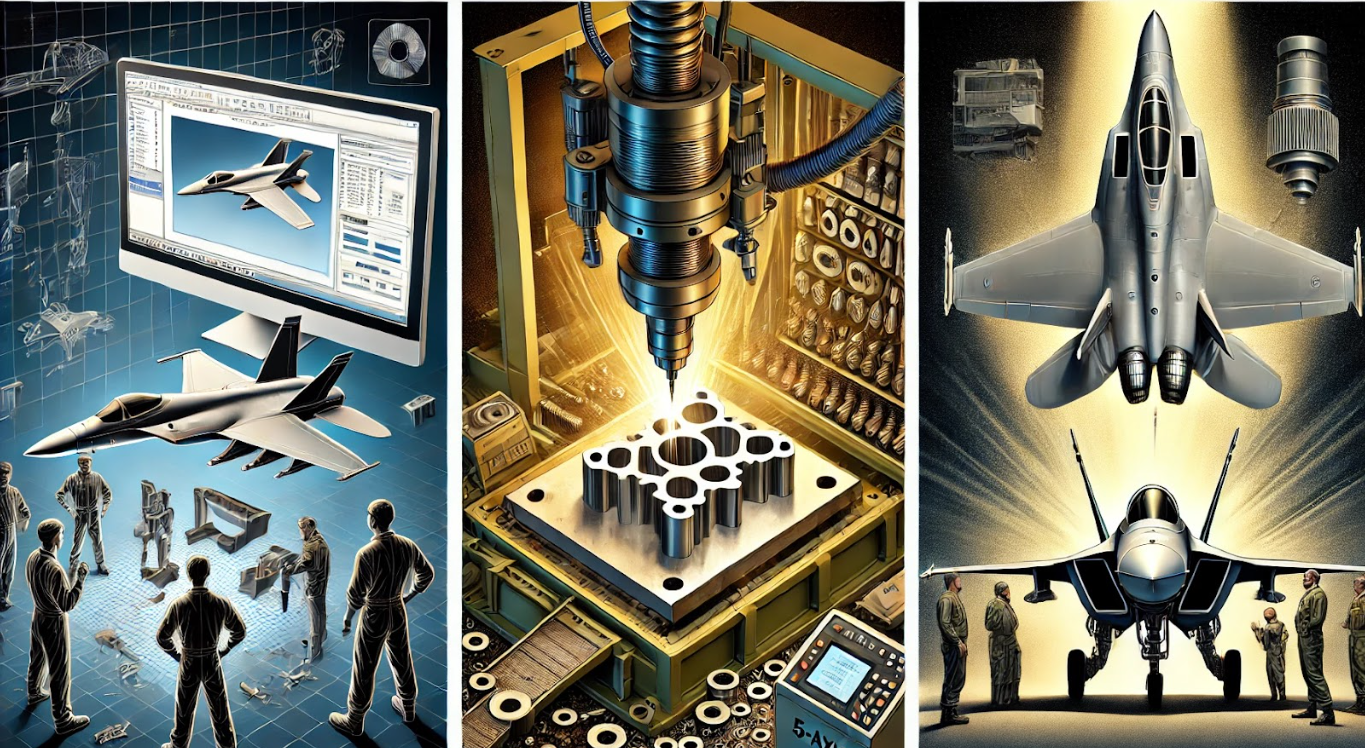

CAD and Engineering Design

The journey begins with the all-important engineering design phase. This initial step is crucial, as we collaborate closely with our defence industry clients to refine and optimize designs for CNC manufacturing. At this stage, we work meticulously to ensure that every specification is tailored to meet the exacting demands of the military. We consider various factors, such as durability, functionality, and manufacturability, so that the components perform reliably under extreme conditions at the lowest price possible.

Our contribution at Ben Machine is to transform these designs into robust and manufacturable solutions that adhere to military specifications before advancing to CNC machining.

CNC Precision Machining and Advanced Manufacturing

With the design in place, we transition into the computer-controlled machining process. This phase involves the critical step of converting CAD data into CAM instructions, generating precise G-code, and setting up the machinery for the task ahead. Our advanced manufacturing capabilities ensure that each defence component is produced with unparalleled precision and accuracy, meeting the stringent requirements of the defence industry.

To support high-precision machining, we utilize cutting-edge technologies like multi-axis CNC machines and specialized tools. At Ben Machine, we also focus on future-proofing our processes, continually innovating to stay ahead of the evolving needs of the defence sector.

For instance, our dip brazing technology offers a precision solution for joints that are difficult to access, creating seamless and highly durable bonds that surpass traditional welding methods. This innovation is particularly beneficial for complex configurations that demand intricate and secure connections.

Quality Control and Inspection

At Ben Machine, we consider quality control to be the foundation of everything we do. Each component undergoes a thorough inspection to ensure it meets the precise specifications required for defence applications. This process not only involves cutting-edge technology but also a dedicated team of experts who meticulously examine every detail of each part.

Our commitment to quality goes beyond simply meeting industry standards. We adhere to and exceed the rigorous benchmarks of AS 9100D and ISO 9001:2015. Every part we produce is subjected to an array of industry-leading testing methods, ensuring it will perform reliably in mission-critical environments. This focus on quality guarantees that components are always delivered to specifications, contributing to the safety and success of military operations.

Assembly and Finishing

Once machining is complete, the next phase of the process is assembly and finishing. Our assembly teams are well-equipped to handle the most challenging projects, bringing manufactured components together into complex systems while adhering to international standards. By leveraging our expertise, we ensure that every assembly is built to perform flawlessly, meeting or exceeding the requirements of AS9100.

In addition to assembly, Ben Machine provides a comprehensive suite of metal finishing services to protect components in transit and ensure they are ready for immediate deployment. From anodizing and chromate conversion to plating and non-destructive testing, our on-site finishing capabilities ensure the durability and longevity of every part, even in the harshest conditions.

Overcoming Challenges and Driving Innovation

Throughout our history, Ben Machine has consistently pushed the boundaries of what’s possible in defence manufacturing. When an aerospace systems supplier needed to reconfigure aerospace technology for the land-based vehicle market, they came to us with a challenge: help us create an updated design for terrestrial applications that is scalable for mass production.

We were engaged because of our expertise in cost-effective, precision engineering. Our experts meticulously dissected the original aerodynamic features to help tailor a robust design for land vehicles yet economical enough for the market’s demands.

Our joint efforts with the client’s design team enabled the removal of non-essential airborne capabilities, resulting in a streamlined, market-competitive system that maintained the technological excellence of its aeronautical lineage.

The journey of creating these critical components started with a 3D CAD design, which was iterated and refined until it became a working product capable of performing in the most demanding environments.

Final Thoughts

Ben Machine excels in producing high-quality, reliable defence components through advanced machining operations and precision engineering. Our dedication to exceeding industry standards and our ability to innovate in the face of complex challenges consistently meets the evolving demands of the defence sector. As a trusted industry partner, we are committed to supporting future defence needs with the same excellence and reliability that has defined our work.

Connect with Ben Machine for high-quality CNC machining services and partnerships, or to learn more about our capabilities in defence component manufacturing.