CNC milling and precision sheet metal fabrication are two valuable manufacturing processes in high-stakes industries like aerospace and military. Incorporating production and CNC welders into these processes enhances the manufacturing of complex and specialized components.

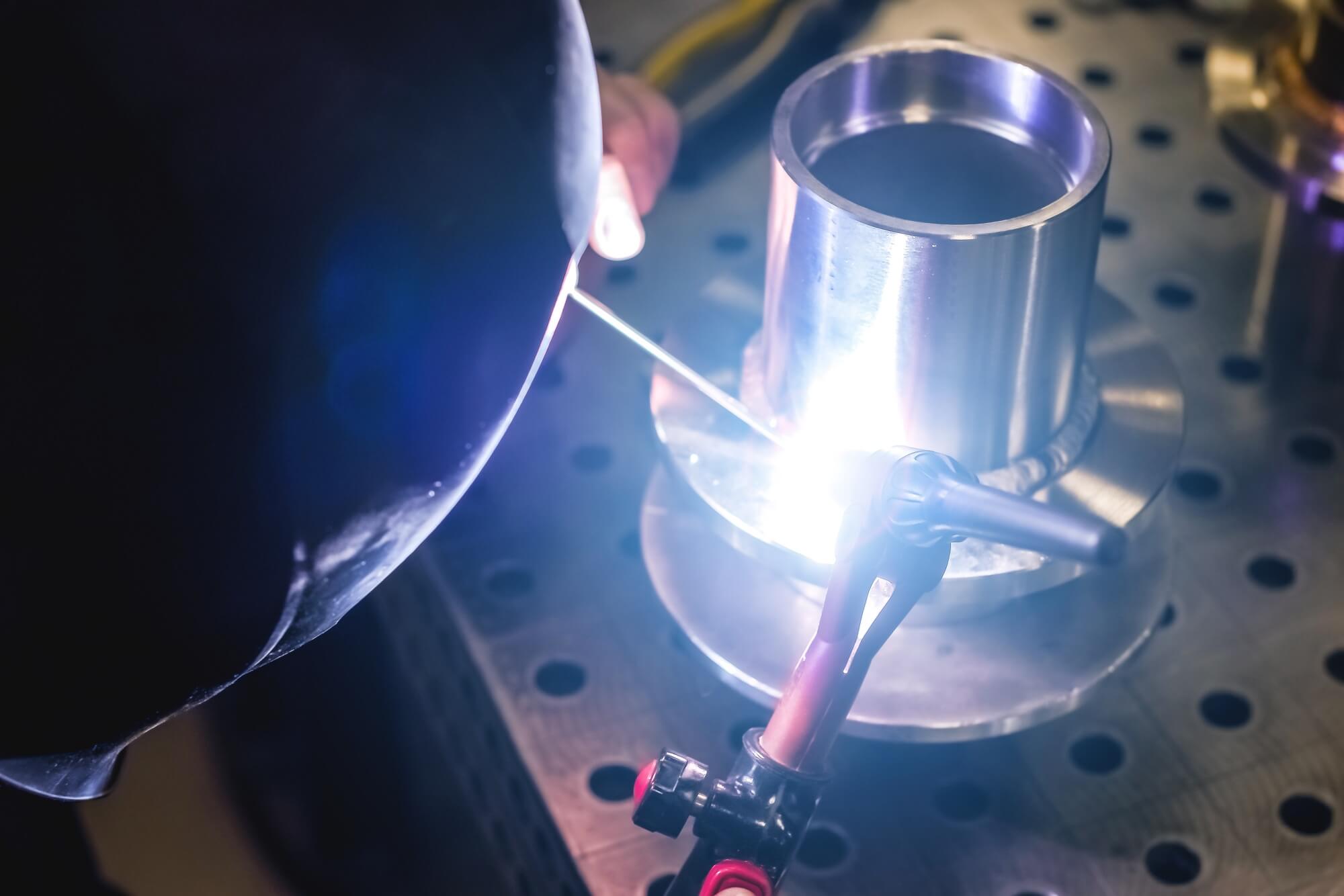

In precision manufacturing, CNC welding bridges the gap between machined parts and final assemblies. It’s the step that turns expertly machined components into fully functional systems—where precision, strength, and reliability all come together. From aerospace structures to medical devices and defence equipment, certified welding ensures that every joint and seam meets the exacting standards these industries demand.

What makes certified welding so critical is its ability to maintain structural integrity while supporting intricate designs. Each weld must align perfectly with engineering specifications and tolerances, leaving no room for error. When combined with advanced CNC machining, welding allows manufacturers to create assemblies that perform flawlessly under extreme conditions.

For buyers and design engineers, certified CNC welding means confidence—knowing every part is built to last, tested for quality, and ready for mission-critical performance.

Why Certified Welding Matters in CNC Projects

Certified welding for CNC-manufactured products ensures structural integrity and adherence to precise specifications. It guarantees high-quality welds that withstand stress and improve durability, ensuring safety and reliability in complex components across critical applications.

Certified welders skillfully join individual components into intricate assemblies. They use their expertise to interpret technical drawings and specifications to execute precise welds, and their certification ensures that these welds meet rigorous standards for strength and quality. In high-stakes environments, these standards aren’t optional; they’re essential.

One of the most essential benefits of certified CNC welding is the prevention of structural defects and premature failure. Every weld becomes a potential stress point, especially where parts experience heavy loads or vibration. Certified welders are trained to recognize these challenges and apply techniques that maintain material strength and dimensional accuracy. This precision ensures that parts not only fit as intended but also perform consistently over time.

For design engineers, certified welding means peace of mind. It ensures that their designs are executed exactly to specification, meeting tolerances without distortion or misalignment. For buyers and decision makers, it reduces production risks, improves reliability, and minimizes costly rework or downtime.

CNC welding also complements other manufacturing processes, such as milling and sheet metal fabrication, by providing the finishing touch that brings complex assemblies together. It transforms a collection of machined parts into a unified, functional structure—where every connection supports long-term strength, precision, and performance.

Certified Welding Processes and Techniques

Ben Machine’s welding team, meeting the rigorous requirements of AS9100, turn CNC-manufactured components into complicated assemblies. We have achieved certification with military, aerospace, and commercial customers for MIG, TIG, spot welding, and brazing. With proficiency in MIG (semi-automatic and automatic) and TIG, or semi-automatic gas tungsten arc welding (GTAW) techniques, our team excels in fusing components made from various materials, including ferrous and non-ferrous metals. No matter the material or gauge thickness, our welders have the certifications and experience to meet even the most stringent industry standards.

Choosing the Right Welding Method

Each welding method has its own advantages and is selected based on the specific requirements of the CNC project:

- MIG (Metal Inert Gas) Welding: Ideal for thicker materials and production runs where efficiency is key. MIG offers high deposition rates and consistent results, making it well-suited for structural applications.

- TIG (Tungsten Inert Gas) Welding: Used when precision and appearance matter most. TIG welding produces clean, high-quality welds on thin materials or critical assemblies that demand tight tolerances—common in aerospace, medical, and defence applications.

- Spot Welding: Typically used for joining sheet metal, this process creates small, strong welds without filler material.

- Brazing: Used to bond dissimilar metals or delicate components, brazing achieves strong joints without melting the base materials, preserving part geometry and surface finish.

The Role of Automation in Modern Welding

Advanced CNC welding often incorporates automated or semi-automated systems to enhance repeatability and consistency. Automation minimizes human variation, ensuring each weld occurs under controlled conditions that meet exact specifications. This control is especially valuable in high-mix, low-volume production environments, where flexibility and repeatable accuracy are both essential.

Working with challenging materials—such as aluminum alloys, stainless steel, and titanium—demands both experience and precision. Each metal presents unique thermal and structural challenges, from managing heat distortion in thin-walled parts to preventing contamination in sensitive alloys.

Quality Control and Inspection Methods

Every project undergoes stringent quality control and inspection procedures. Certified inspectors evaluate each weld using non-destructive testing methods, such as visual inspection, X-ray, or dye penetrant testing, to confirm structural integrity and compliance. This attention to detail ensures every assembly meets performance, safety, and reliability standards before delivery.

Certifications and Standards

Ben Machine holds specific welding certifications, such as MIL-STD-2219 and AWS D17.1, for military welding. The requirements for military welding can be up to five times more stringent than those for commercial purposes.

Our expert welders are also certified to the Canadian Standards Association (CSA) W47.1 and W47.2 welding specifications. Each certification is validated by the Canadian Welding Bureau (CWB), ensuring that our processes meet the highest levels of quality and compliance across all projects.

Training and Certification of Ben Machine Welders

Every welder at Ben Machine undergoes rigorous training in basic metallurgy, welding drawings, layout, and fabrication. They must pass certification exams that verify both their technical knowledge and practical ability to perform under real-world conditions. Some welders have completed extensive apprenticeship programs, combining years of hands-on experience with formal technical education to deliver consistent, high-quality results.

For buyers and design engineers, these certifications are more than just formalities—they represent assurance of safety, reliability, and regulatory compliance. Certified welding processes guarantee that every joint meets or exceeds the performance standards required by the application, whether it’s a commercial assembly or a defence-grade component.

Meeting Aerospace and Military Requirements

Different industries demand different levels of precision. Aerospace and military applications, for instance, require absolute adherence to specification tolerances and materials traceability. Certified CNC welding ensures that every weld is documented, inspected, and traceable—providing transparency and confidence at every stage of production.

For Canadian manufacturers and procurement teams, partnering with a CWB-certified and AS9100-compliant machining company like Ben Machine provides peace of mind. It means that they produce their parts under verified procedures that meet the most demanding international standards—without compromising on quality, performance, or accountability.

Applications of Certified CNC Welding

Certified welders can create sophisticated optical assemblies that demand high precision, such as:

- Laser Systems: Components that focus and direct laser beams require precise alignment and welding to maintain functionality and accuracy. Even a slight misalignment can alter beam focus, making certified CNC welding essential for consistent performance.

- Aerospace Sensor Systems: These require flawless micro-welding of sensitive parts to ensure accurate data collection under extreme conditions like vibration, temperature shifts, and pressure changes.

- Medical Imaging Devices: MRI and CT scanners contain welded components that must be perfectly aligned to ensure the reliability and clarity of diagnostic images.

Each assembly requires meticulous attention to detail, and certified welders contribute their specialized skills to ensure optimal assembly and performance. Our assembly services demand care and expertise, particularly with complex projects. This service includes meticulous planning and execution of critical sequencing, with each step building on the previous one. Handling components involve precise measurement, careful alignment, and secure fastening to prevent damage and maintain integrity.

Broader Use Across Advanced Manufacturing

Beyond optical and medical systems, CNC welding plays a vital role in many other advanced manufacturing applications:

- Robotics and Automation Systems: Structural frames, sensor housings, and precision joints require welds that can handle repetitive motion and high torque without failure.

- Defence Equipment: From armoured housings to electronic enclosures, welding ensures that components maintain integrity under the harshest operational environments.

- Industrial Machinery: Welded assemblies provide the strength and vibration resistance needed to keep production equipment reliable and efficient.

Integrating welding into CNC projects adds significant technological diversity, enhancing both simple and advanced constructions. Welding enables the seamless integration of diverse materials and geometries, providing structural strength and long-term stability that bolted or riveted joints can’t consistently achieve.

The expertise of certified welders ensure precision and consistency, accommodating a wide range of materials, thicknesses, and tolerances. This capability is crucial for industries that demand flawless execution—facilitating innovation in both design and performance.

Example: Multi-Material Aerospace Sensors

Consider a compact aerospace sensor assembly made of multiple materials, including aluminum for lightweight strength and titanium for temperature resistance. Certified welders must fuse these materials without compromising alignment or surface finish. Using TIG welding under controlled conditions, the weld achieves both structural integrity and dimensional precision, allowing the sensor to function reliably during flight.

Whether the project involves micro-welds for medical devices or heavy-duty joints for industrial applications, certified CNC welding ensures that every part performs as intended—safely, reliably, and with exceptional repeatability.

Benefits of Integrating Welding into CNC Projects

Including welding in CNC projects adds significant technological diversity, enhancing both simple and advanced constructions. It provides structural strength and stability—key qualities for industries that rely on precision and durability.

When CNC welding is integrated early in the design and manufacturing process, it opens the door to greater design flexibility. Engineers can join multiple materials, complex geometries, and different component types into a single, cohesive assembly. This flexibility allows for creative solutions to engineering challenges, such as reducing weight while maintaining strength or improving thermal performance by combining metals with distinct properties.

From an operational standpoint, integrating welding offers significant production advantages:

- Reduced assembly time: Components that are welded directly during or after CNC machining require fewer fasteners and less manual assembly.

- Improved precision: Welded joints eliminate the slight movement or loosening that can occur with mechanical fastening, ensuring consistent performance over time.

- Fewer post-processing steps: Clean, accurate welds minimize the need for grinding, rework, or alignment adjustments.

For buyers and design engineers, the result is a more efficient and dependable manufacturing process. Certified CNC welding ensures that parts meet exact specifications the first time—reducing lead times, improving consistency, and enhancing overall product quality.

Ultimately, integrating welding into CNC projects supports a higher standard of manufacturing excellence. It delivers assemblies that not only meet performance expectations but also offer long-term reliability, helping companies achieve greater value and durability from every component.

Conclusion: A Trusted Partner in Certified CNC Welding

Certified welders are critical to the success of advanced CNC manufacturing projects. Their expertise ensures every joint, seam, and structure meets the highest standards of strength, accuracy, and reliability. When combined with the precision of CNC machining, certified welding transforms complex designs into durable, high-performance assemblies that excel in demanding environments.

For companies operating in aerospace, defence, medical, and other precision-driven sectors, CNC welding isn’t just an add-on—it’s a strategic investment in quality, safety, and long-term performance. The assurance that every weld is completed by a certified professional following verified procedures gives buyers and engineers the confidence they need when sourcing mission-critical components.

Businesses seeking dependable fabrication and assembly services should consider partnering with a machining company that meets these exacting standards. Ben Machine is one of the leading certified welding manufacturers whose capabilities, advanced CNC expertise, and commitment to compliance under AS9100 and CWB certifications, help clients gain a trusted partner ready to tackle even the most complex manufacturing challenges—with precision built into every weld.