Nanotechnology revolutionizes manufacturing by enabling precision at molecular levels, fostering innovations in materials and products. It provides significant improvements in properties such as strength and durability while enhancing product performance and efficiency.

Nanotechnology involves manipulating matter at nanoscales (1-100 nanometers). Staying ahead of advances in CNC machining is crucial for ensuring optimal performance, quality, and competitiveness, incorporating the latest technologies for precise and efficient production.

Understanding Nanotechnology in CNC Machining

As mentioned, nanotechnology is manipulating materials at an atomic or molecular scale. Nanotechnology in CNC machining enhances precision, material properties, and tool performance. Machinists can achieve superior finishes, improved durability, and reduced wear by integrating nanoparticles into cutting tools, cutting fluids, and coatings. As a result, the machining process is more efficient with higher-quality outputs.

Canada is pioneering in this technological integration, investing in research and development to lead global advancements in CNC machining, thereby ensuring its manufacturing sector remains competitive and innovative.

Improving Machine Tool Coatings with Nanotechnology

Nano-coatings offer significant increases in tool durability and performance by providing superior hardness, thermal stability, and resistance to wear and corrosion. For example, carbide tools with diamond nano-coatings maintain their cutting edge longer, resulting in consistent precision and reduced downtime.

Nano-coated tools require fewer replacements, enhancing productivity and lowering costs. Additionally, the extended tool life minimizes waste and the environmental impact of frequent tool production and disposal. Consequently, nano-coatings contribute not only to economic efficiency but also to sustainable manufacturing practices.

The Role of Nanolubricants in Machine Performance

Lubricants are essential in CNC machining for reducing friction, cooling, and minimizing wear on tools and machine components. Nanofluids, enhanced with nanoparticles, surpass traditional lubricants by providing superior lubrication and thermal stability. They form a robust, microscopic film that reduces friction more efficiently, resulting in enhanced precision and consistency.

In addition to significantly reducing wear and increasing tool life, these nanofluids allow increased feeds and speeds to help increase production. The advanced properties of nano lubricants contribute to improved CNC machine performance, reduced maintenance costs, and increased operational longevity, making them invaluable in high-precision machining operations.

Advanced Materials and Nanotechnology

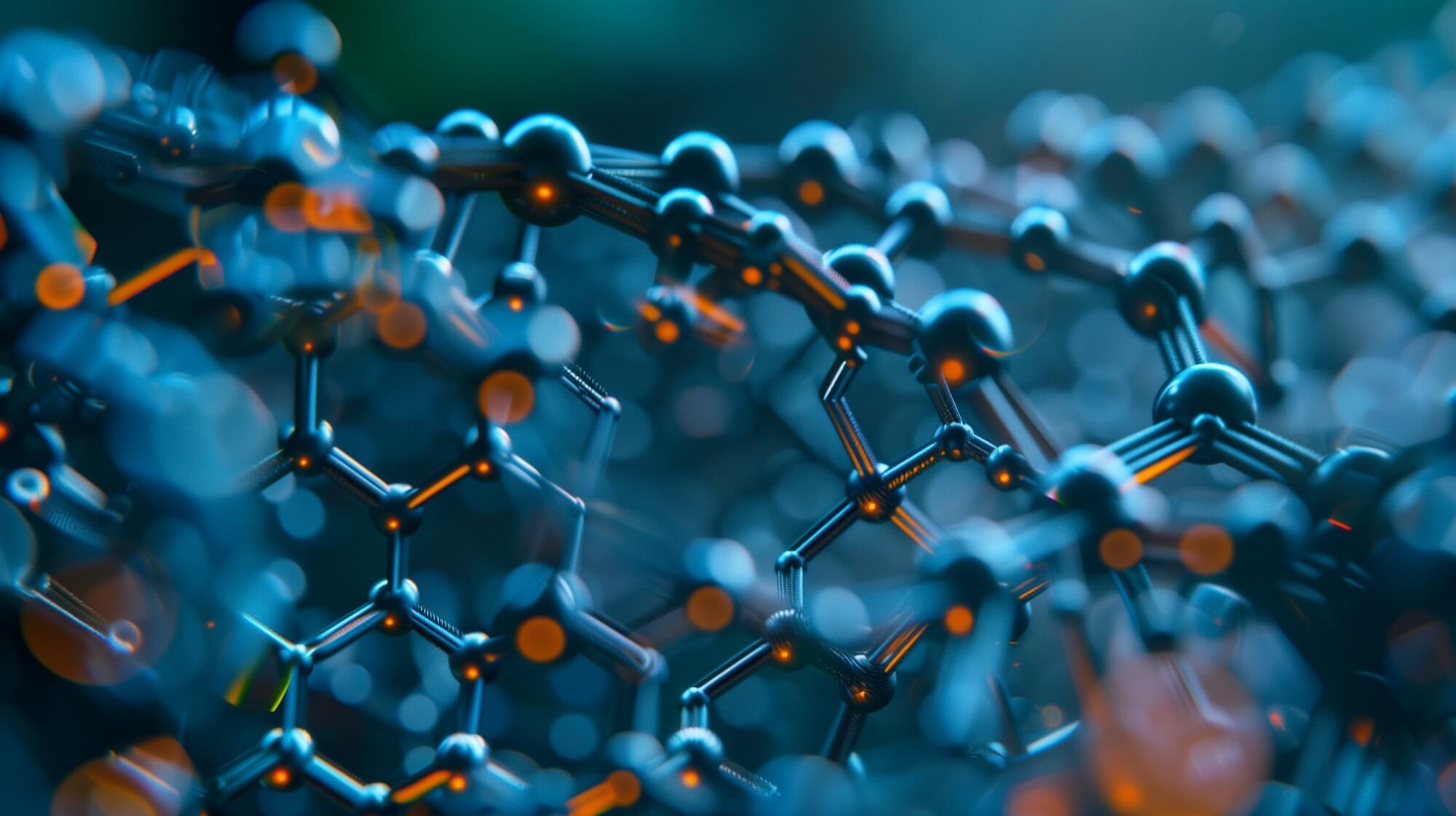

Cutting-edge materials like carbon nanotubes (CNTs) revolutionize CNC machined products by offering exceptional strength-to-weight ratios, electrical conductivity, and thermal properties. These nano-engineered materials allow for lighter, stronger, and more durable components, pushing the boundaries of traditional manufacturing capabilities.

Design engineers are pivotal in this transformation by incorporating these innovative materials into their designs, ensuring that products capitalize on nano-material advantages. This integration requires understanding material properties and machining processes, paving the way for highly efficient, next-generation products with enhanced performance and extended lifespans.

The Future of CNC Machining with Nanotechnology

Future developments in nanotechnology will likely revolutionize CNC machining through advancements in precision, material properties, and tool efficiency. Emerging nano-engineered materials and coatings will enable even more precise and faster machining processes, reducing production costs and enhancing product quality.

Decision-makers should consider the long-term benefits of investing in nano-enhanced CNC processes, including increased productivity, reduced tool wear, and lower environmental impact. Such investments promise a competitive edge by enabling the manufacture of superior, innovative products while fostering sustainable practices.