CNC machining has been vital to the military and defence sectors for decades. It all started after World War II, when the demand for complex parts was high. As technology advanced, so did the potential of CNC machining, with emerging innovations set to redefine the industry.

Over the years, CNC machining has become more advanced and versatile. Today, advancements in technology mean CNC machines can operate more efficiently. In this blog, we’ll take a quick look at the future of CNC machining in the military sector.

The Historical Significance and Technological Evolution

CNC machining’s journey from the necessity of World War II to modern-day defence innovation reveals a remarkable evolution. In the wake of the war, demand for mass-produced yet complex parts surged, giving birth to the first automated machines.

Today, the Canadian defence industry continues to capitalize on the unprecedented growth and enhancement of CNC technologies, embracing them faster than ever. The pace at which new advancements are integrated into military applications underscores Canada’s commitment to staying at the forefront of defence technology.

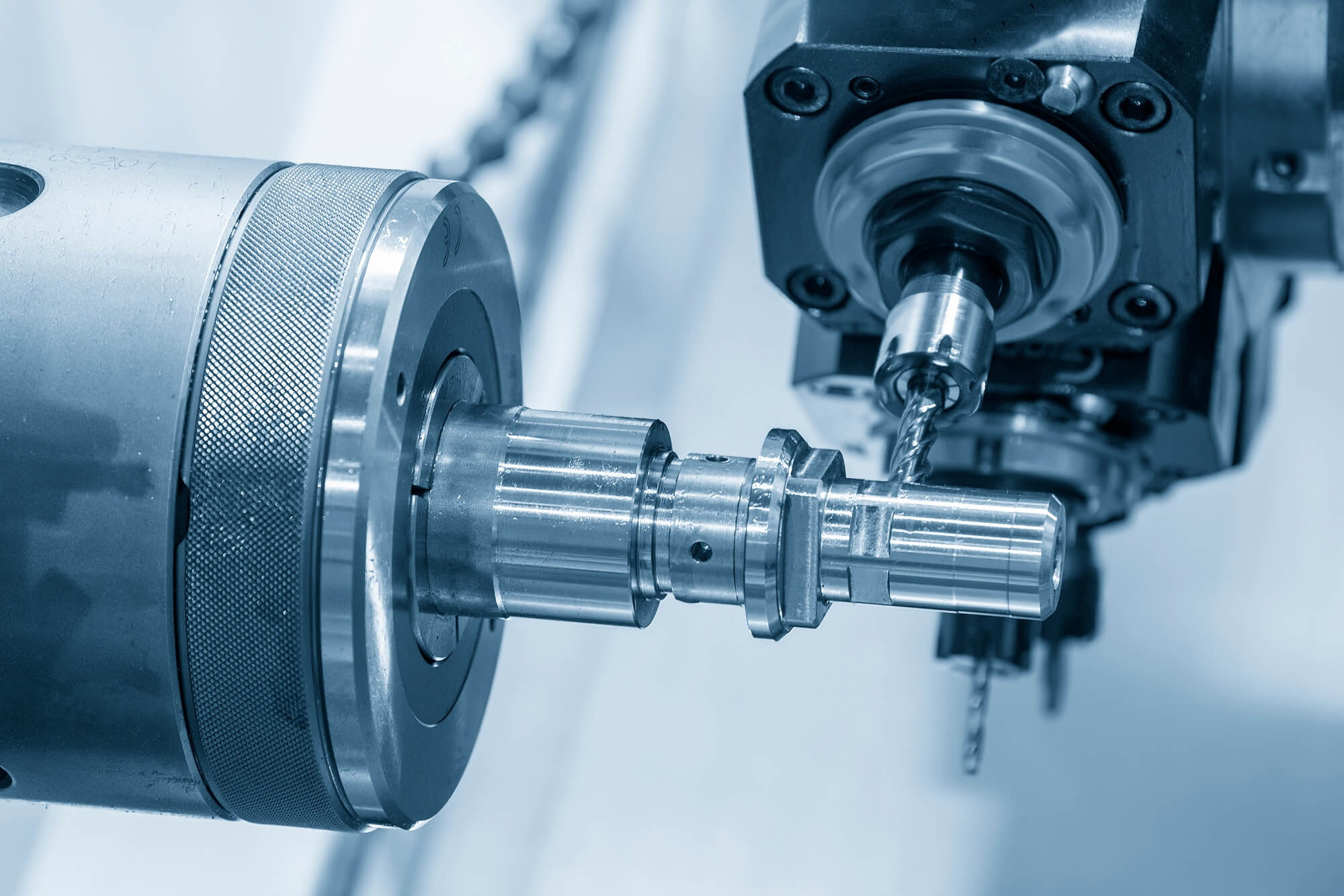

Canadian defence has seen significant evolution in its technological capabilities over the years. For instance, the adoption of multi-axis machining centres allows for the production of intricate components with high precision, vital for the complex machinery of defence applications. These Canadian defence industry advancements demonstrate the sector’s progress and highlight the role of CNC machining as an enabler of national security and defence initiatives.

Advanced Technologies Redefining Precision and Reliability

Military and defence equipment must perform in the harshest environments—meaning the parts used must meet strict standards for durability, accuracy, and quality. That’s where advanced CNC machining technologies come in.

Modern techniques like high-speed machining and through-coolant machining help meet these demands by:

- Reducing cycle times for faster turnaround on critical components

- Maintaining tight tolerances required for reliable performance

- Improving surface finishes, which enhances durability and function

- Supporting hard-to-machine materials, such as titanium and hardened alloys

Canadian manufacturers are putting these tools to work. By applying high-speed machining, for example, they’ve shortened production times and improved efficiency—making it easier to meet the urgent needs of the armed forces.

These advancements aren’t happening in isolation. Ongoing collaboration between defence agencies and Canadian CNC shops is helping to:

- Accelerate innovation in part design and production

- Strengthen domestic manufacturing capabilities

- Boost national security by reducing reliance on foreign suppliers

In short, advanced machining technologies are helping Canada build stronger, more reliable defence systems—faster and more efficient than ever before.

Specific Applications for the Military & Defence Industry

CNC machining services manifest in various defence applications within Canada’s military and defence industry and are pivotal in enhancing operational capabilities and ensuring national security. These services enable the production of custom-fitted parts where durability and exact dimensional tolerances are required for performance and safety in combat zones. These include armoured vehicles, such as:

- Personnel carriers

- Tanks

- Reconnaissance units

The intricate needs of aerospace systems also benefit heavily from CNC machining, particularly in manufacturing precision aircraft components. These parts must adhere to stringent tolerances to maintain reliability at high altitudes and under extreme mechanical stresses. They include (but are not limited to):

- Turbine blades

- Engine housings

- Structural supports

Communication devices used in the military—from satellite uplinks to encrypted radio systems—rely on machined components operating flawlessly under adverse conditions, including:

- Extreme temperatures

- Vibration

- Electromagnetic interference

CNC machining supports mission-critical innovations, underscoring its indispensable role in Canada’s defence manufacturing environment. These innovations exist in:

- Surveillance

- Navigation

- Combat support systems

From prototyping to full-scale production, CNC machining consistently produces parts with tight tolerances using specialized materials, such as titanium or hardened alloys. The combination of precision machining and durable materials ensures that these devices remain operational.

Swiss Turning and Complex Machining

The unique and demanding requirements of the Canadian military have significantly influenced advanced techniques like Swiss turning and multi-axis machining. They need exceptionally intricate parts, such as the miniaturized internal components of secure communication devices or the high-precision elements within optical and targeting instruments, and it has propelled the evolution of these machining practices to new heights of technical sophistication.

These methods enable the creation of military components with minute tolerances and complex geometries that traditional machining methods cannot achieve. Canadian defence projects have capitalized on these advanced manufacturing capabilities, with a notable example being the Canadian Navy’s procurement of highly complex, custom-machined parts for its latest class of advanced warships. These components, which often form critical systems such as navigation arrays, weapons interfaces, and propulsion assemblies, must perform reliably in challenging marine environments.

Through our diversified range of CNC capabilities, including advanced Swiss turning, 5-axis machining, and micro-machining, we help fulfill these complex military requirements with the precision, speed, and high quality of today’s defence standards.

The Role of AI and Industry 4.0

Integrating Artificial Intelligence (AI) and the broader principles of Industry 4.0 is transforming CNC machining in Canadian military and defence manufacturing. These technologies enable smarter, more adaptive systems that reshape traditional production models.

Benefits of AI and Industry 4.0 include:

- Predictive maintenance to reduce unplanned downtime

- Real-time data analytics for process optimization

- Enhanced quality control and equipment availability

According to McKinsey & Company, predictive maintenance using AI can:

- Increase equipment availability by up to 20%

- Cut inspection costs by 25%

- Reduce annual maintenance costs by up to 10%

At the same time, Industry 4.0 is ushering in a new era of manufacturing intelligence. With the implementation of interconnected machines, real-time data analytics, and intelligent automation, production lines can now self-optimize for greater efficiency, precision, and scalability. In addition to reducing turnaround times, 4.0 ensures a higher level of quality control, both of which are vital in defence applications with little room for error.

These technologies are already beginning to demonstrate their value. For example, early-stage pilot programs using AI to optimize the maintenance schedules of military vehicles, such as armoured personnel carriers and logistics trucks, have led to improvements in operational readiness. These systems can better anticipate servicing needs, resulting in fewer unexpected mechanical failures and increased vehicle availability.

As these technologies mature, they will become integral to Canada’s defence manufacturing landscape, driving innovation and strategic capability.

Cybersecurity: A Top Priority in CNC Machining

Given the increasingly networked nature of industrial machinery and the integration of digital technologies in modern manufacturing, cyber threats pose a significant risk to CNC operations, specifically within the military, where security breaches can have far-reaching consequences.

Recognizing the importance of safeguarding sensitive data and operational continuity, Canada’s defence industry has taken a proactive stance by implementing comprehensive cybersecurity measures designed to protect high-value manufacturing infrastructure. These efforts include:

- Partnering with national security and intelligence agencies

- Investing in threat detection and access control systems

- Using encrypted communications

Additionally, industry stakeholders are shaping and adopting cybersecurity standards tailored to the unique vulnerabilities of defence-related CNC processes, helping to ensure that advanced manufacturing remains efficient and secure in the face of evolving cyber challenges.

Prototyping and Rapid Manufacturing for Defence

Prototyping and rapid manufacturing support the Canadian military’s ongoing efforts to maintain a technological edge in an increasingly complex and unpredictable global security environment. The ability to quickly adapt and innovate is more crucial than ever because of Canada’s unique geopolitical position—spanning vast and often remote territories—and the constantly evolving nature of modern threats.

Rapid prototyping enables defence engineers and manufacturers to move swiftly from concept to physical model, allowing for iterative design testing and refinement in shorter timeframes. Prototyping accelerates the development of advanced defence technologies, such as:

- Surveillance systems

- Unmanned platforms

- Communication devices

This ensures that Canadian forces can respond effectively to emerging challenges.

Rapid manufacturing capabilities enable the production of mission-specific components on demand, reducing reliance on long supply chains and enhancing overall operational agility.

Automation in CNC Machining for Defence

Automation is the cutting edge of modern CNC machining and is increasingly vital within the defence sector. For the Canadian military—where precision, reliability, and speed are non-negotiable—advanced CNC machining offers an effective combination of benefits:

- These systems significantly boost production efficiency by running continuously with minimal human intervention while ensuring consistency across parts.

- This repeatability and accuracy are critical for applications where the slightest deviation can impact performance or safety.

- Automation enhances workplace safety by reducing direct operator involvement in potentially hazardous machining tasks.

As defence technology advances, the demand for precision components continues to grow—especially with the rising use of unmanned vehicles, drones, autonomous ground systems, and robotic platforms in modern military operations. CNC machining is uniquely suited to meet these needs, enabling the precise and repeatable fabrication of intricate parts for sensors, propulsion units, control systems, and structural frames.

As this trend continues, automation will support faster production cycles and play a key role in maintaining the technological superiority of Canada’s defence manufacturing.

Advancing Canadian Defence with Smarter CNC Solutions

Integrating AI, advanced manufacturing technologies, and a commitment to cybersecurity drives a transformative shift across the CNC machining industry, particularly within military and defence applications. These innovations are not simply enhancements but foundational to building a more agile, responsive, and resilient manufacturing ecosystem.

By embracing these future-proof technologies, we empower the Canadian military and defence sectors to elevate their most critical systems’ performance, precision, and reliability—from frontline vehicles and aircraft to secure communication networks and autonomous platforms.

The continued adoption of AI-driven analytics, automated machining, and fortified cybersecurity frameworks will position Canada’s defence manufacturing capabilities to shape the future of global innovation. These advances ensure that our military is not only equipped to meet today’s operational demands but is also strategically prepared to confront and adapt to tomorrow’s complex and evolving threats.

In this rapidly changing landscape, staying ahead means investing in more innovative, more connected, and secure manufacturing solutions—and that’s precisely where the future of CNC machining is headed.