Manufacturing today is no longer an either-or decision between traditional CNC machining and 3D printing. Instead, innovative manufacturers are finding value in combining both additive and subtractive manufacturing techniques. By combining these methods strategically, it’s possible to accelerate product development, minimize waste, enhance part quality, and reduce production costs.

Additive manufacturing (AM), also known as 3D printing, builds parts layer by layer using a variety of materials, including polymers, metals, ceramics, and others. Subtractive manufacturing (SM), on the other hand, is what most people associate with CNC machining. It involves removing material from a solid block to create a finished part.

Each method brings unique strengths to the table. Used together, they allow shops like Ben Machine to deliver precision results, even on high-mix, low-volume jobs.

This article explores how additive and subtractive manufacturing can work together, not just as alternatives but as complementary tools in a modern machine shop’s toolkit. We’ll cover their advantages, practical integration strategies, industry use cases, and how Ben Machine evaluates the appropriate approach for every job.

Understanding the Basics: Additive and Subtractive Manufacturing

Both additive and subtractive methods have distinct and complementary roles in the manufacturing process. Understanding their fundamental differences—and how they can work in tandem—is key to making informed production decisions.

Additive Manufacturing (AM):

- Builds parts layer by layer from a digital 3D model

- Commonly uses thermoplastics, resins, metals, and composite materials

- Excellent for creating complex internal geometries and lightweight structures

- Especially valuable for rapid prototyping, where design validation is essential

- Allows for fast iteration without the need for tooling

Subtractive Manufacturing (SM):

- Involves removing material from a solid workpiece using cutting tools, drills, or lathes

- Typically performed on CNC machines, which offer automated, repeatable precision

- Provides an excellent surface finish and tight dimensional tolerances

- Best suited for parts that require high strength, durability, or exact material properties

- Offers greater reliability for mission-critical or regulated applications

Key Differences at a Glance:

| Feature | Additive Manufacturing | Subtractive Manufacturing |

| Material use | Adds material where needed | Removes excess material |

| Tolerances | Moderate | Very high |

| Surface finish | May require post-processing | High-quality finish |

| Cost efficiency | Best for prototypes/small runs | Better for larger runs and prototypes |

| Ideal use | Complex shapes, light materials | Durable, functional production parts |

When Is Each Method Best?

- Additive: Ideal for small, intricate aerospace brackets made from titanium or PEAK; also practical for quick-turn prototypes and custom medical components

- Subtractive: The go-to for medium to high-volume runs of precision aluminum enclosures, defence housings, or hardened steel components requiring critical tolerances

Ultimately, the best choice depends on part geometry, material requirements, production volume, and turnaround expectations. Increasingly, manufacturers are finding value in blending both methods—using AM for design flexibility and SM for final performance and functional requirements.

How Additive Manufacturing Supports CNC Machining

AM doesn’t replace CNC machining—it enhances it. When used strategically, it can reduce lead times, lower costs, and improve part quality while offering greater design flexibility in the early stages of development.

One of the most common ways additive supports CNC workflows is through rapid prototyping. AM enables the fast, iterative development of part designs without the need for expensive tooling or moulds. Engineers can validate concepts, test fit and function, and refine part geometry before moving to full-scale CNC production. This process not only reduces time-to-market but also minimizes material waste and design errors.

Another key area where additive plays a supporting role is in the production of jigs, fixtures, and tooling. These components are crucial for CNC setup accuracy and repeatability. By 3D printing these items in-house, shops like Ben Machine can drastically cut the time and cost involved in preparing a new job for production. Custom fixtures that might take days or weeks to machine can be printed in a matter of hours, improving overall efficiency.

Ben Machine also integrates additive processes into investment casting. Stereolithography (SLA)—a form of high-resolution 3D printing—is used to create casting moulds. These resin-based moulds replace traditional wax patterns, reducing both lead times and tooling costs.

Case Study: Ben Machine’s SLA Workflow

Ben Machine uses SLA to support investment casting workflows. Here’s how it works:

- A digital model of the mould is 3D printed in resin using SLA

- The SLA-printed mould is used in place of wax to create investment castings

- Once cast, the part is CNC machined to meet tight tolerance and surface finish requirements

Benefits of this hybrid approach include:

- Eliminates the need for custom tooling or wax patterns

- Accelerates lead times for prototype and production parts

- Enables customers to test form, fit, and function before final production

- Reduces rework and downstream machining errors

- Allows for small-batch production without traditional moulding costs

This workflow is particularly advantageous for clients with evolving part designs or projects that require short production runs. Ben Machine continues to refine and expand this process to suit a variety of geometries, alloys, and end-use requirements—helping customers bring products to market faster and with greater confidence.

AM and SM work together to form a powerful team, enabling manufacturers to optimize both speed and precision in their operations.

Advanced Materials in Additive Manufacturing

As AM transitions from prototyping to production, the range of materials available has expanded significantly, unlocking new possibilities across industries that demand performance and precision.

PEAK polymers, for example, offer outstanding thermal and chemical resistance. These high-performance plastics can withstand extreme temperatures, making them ideal for aerospace ducting, engine components, and surgical instruments. Their strength-to-weight ratio rivals that of metals in many applications while offering corrosion resistance and biocompatibility.

Carbon fibre-reinforced materials are another leap forward. These composites combine the lightweight nature of polymers with the stiffness and strength of carbon fibres. They are well-suited for structural parts such as UAV brackets, robotics arms, and defence components where both performance and portability matter. The directional strength properties of these materials can also be tuned based on how they are printed.

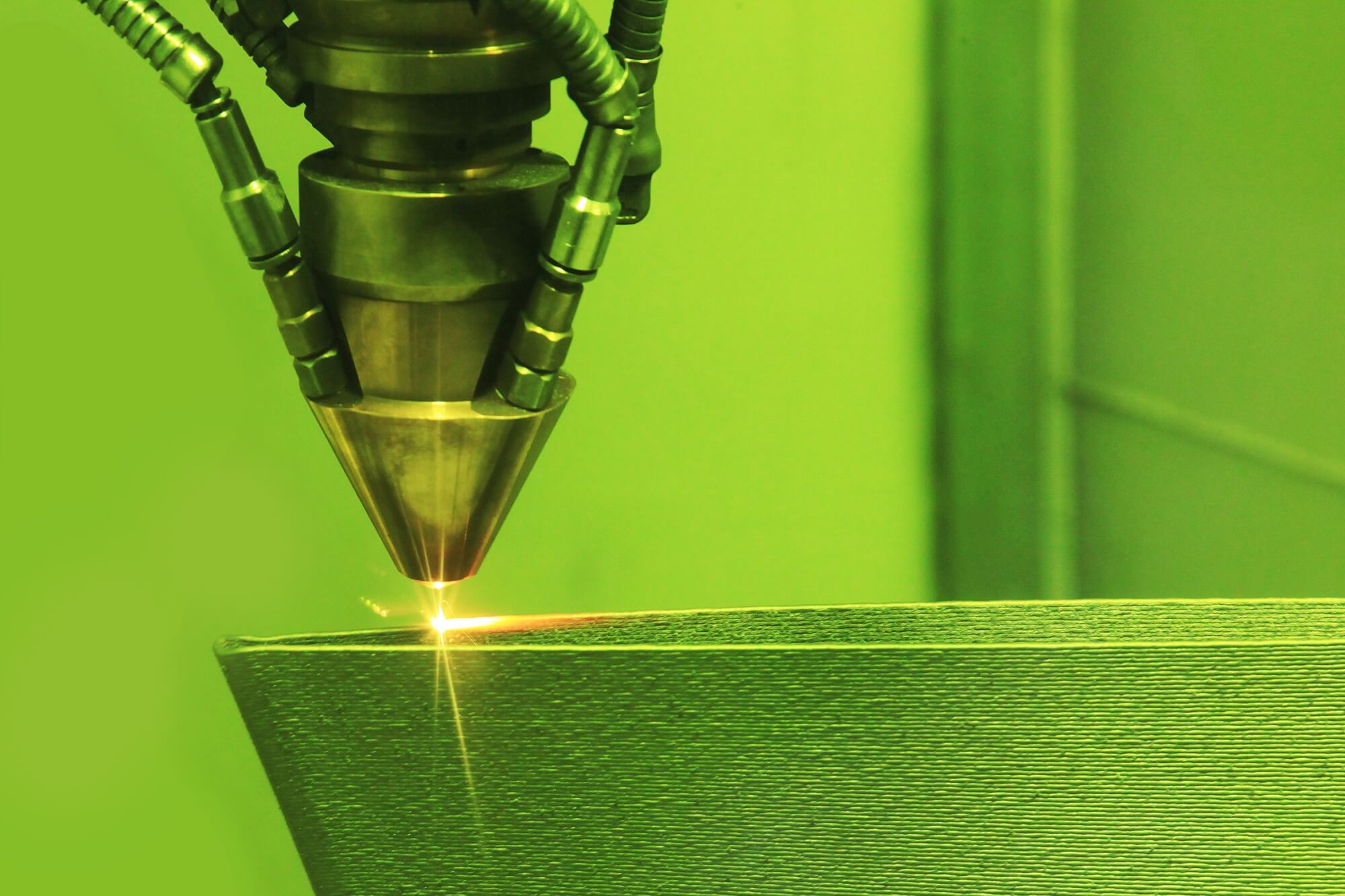

Metal additive manufacturing is the most transformative. Materials like titanium and Inconel—both known for being costly and challenging to machine—can now be printed layer by layer. This is especially beneficial for small parts with intricate geometries, where machining from billet would result in high material waste. Titanium’s exceptional strength-to-weight ratio and corrosion resistance make it a top choice for aerospace applications. At the same time, Inconel excels in high-temperature environments, such as those found in turbine engines.

Because these materials are expensive and often difficult to process through traditional methods, AM becomes an ideal solution when used selectively. The upfront cost may be higher, but the savings in material waste, reduced tooling, and improved part performance can justify the investment.

Whether it’s an aerospace bracket, a spinal implant, or a precision sensor housing, the strategic use of advanced AM materials gives manufacturers more control over the balance between cost, function, and manufacturability.

Cost-Effectiveness, Material Efficiency, and Waste Reduction

Combining additive and subtractive manufacturing creates clear cost and sustainability advantages—especially for small production runs and complex parts.

AM builds components layer by layer, using only the material necessary to create the part. This contrasts with SM, which removes material from a solid block—often generating considerable waste, particularly when working with expensive metals like titanium or Inconel. By leveraging AM for rough geometry and SM for final tolerances, manufacturers can significantly reduce raw material usage and scrap.

Reducing Waste and Machining Time

This material efficiency is especially valuable when dealing with costly or difficult-to-machine materials. With additive manufacturing, there’s no need to purchase oversized billets or worry about excessive cutting time. Instead, a near-net-shape part can be printed and then precisely finished using CNC machining. The result is less waste, less machining time, and faster delivery.

Cost Advantages for Short-Run Production

AM also eliminates the need for expensive tooling, moulds, or dies, making it ideal for short-run production or prototyping where tooling costs would otherwise make the project more expensive. Once the form is validated through additive methods, subtractive processes can bring it to spec—ensuring surface finish, fit, and functional durability.

Efficiency Gains Through Hybrid Workflows

From a labour perspective, the hybrid approach reduces manual setup and rework. With less time spent resetting machines or remaking parts due to design errors, productivity improves across the board.

In short, hybrid workflows combine the best of both worlds: AM reduces waste and tooling costs, while CNC ensures precision and repeatability. Together, they offer a smarter path to efficient, high-quality manufacturing—especially for complex or low-volume parts where margins and material use matter most.

The Role of Hybrid Manufacturing

Hybrid manufacturing systems—machines that combine additive and subtractive processes within a single platform—are an exciting innovation in modern production. These machines can 3D print a part close to its final shape and then immediately machine it to specification, all without requiring a change in setups. In theory, this enables greater speed, efficiency, and integration.

However, the technology is still in the process of maturing. Current hybrid machines come with steep price tags, complex maintenance requirements, and software limitations. Material compatibility and consistent accuracy remain challenges, especially for high-precision applications in aerospace, defence, or medical manufacturing.

Ben Machine sees potential in hybrid systems but is cautious about adopting them prematurely. We are closely monitoring the technology’s evolution while prioritizing reliability and repeatability for our customers.

Currently, we employ a practical hybrid workflow that combines separate additive and subtractive processes. For example, SLA is used to create investment casting moulds, and CNC machining finishes the part to tight tolerances. This setup provides many of the benefits of full hybrid machines—speed, flexibility, and reduced tooling—without the technical risks or high costs.

As machine capabilities improve and integration becomes more seamless, we will continue to evaluate hybrid options. But rather than chasing trends, our focus remains on delivering precise, cost-effective parts through proven methods tailored to each job’s requirements.

Use Cases by Industry

Hybrid manufacturing workflows are gaining traction across multiple industries, particularly those that demand high precision, low-volume production, or customized parts. By combining the flexibility of AM with the accuracy and finish of CNC machining, manufacturers can tailor their processes to meet the specific requirements of each application.

Aerospace

In the aerospace industry, weight reduction and material performance are crucial. AM enables the creation of lightweight titanium brackets with complex internal geometries that would be difficult—if not impossible—to machine alone. These parts are then post-machined using CNC equipment to ensure tight tolerances, mating surfaces, and compliance with aerospace standards.

Defence

Defence projects often involve small-batch, rugged parts that must endure harsh environments. Hybrid workflows support this by enabling the low-cost production of complex housings or mounts using carbon fibre-reinforced polymers or metal AM. CNC machining then finalizes the dimensions and adds precise features needed for field reliability.

Medical

The medical industry benefits from the high customization possible through additive manufacturing. AM can print patient-specific implants and surgical guides from biocompatible materials, and then they can be CNC-machined for optimal fit, finish, and sterilization requirements. This dual approach enhances patient outcomes and reduces turnaround times.

Industrial

In industrial settings, additive methods are used to produce jigs, fixtures, and tooling with intricate internal channels or custom profiles. CNC machining then refines contact points or surface finishes where wear resistance is essential. This is especially helpful for short-run, high-precision manufacturing setups.

Across all these sectors, hybrid manufacturing provides a flexible and cost-effective path to produce components that meet performance, compliance, and delivery requirements with greater efficiency.

Limitations and Challenges of Additive Manufacturing

While additive manufacturing opens the door to new design possibilities and material efficiencies, it does have limitations that make it unsuitable for many projects. For most jobs, especially those involving high-volume production, AM remains too expensive compared to traditional CNC machining. The technology is best suited for smaller parts made from high-value or difficult-to-machine materials, where material savings and design flexibility justify the cost.

Surface finish can also be a constraint. Most 3D-printed parts require secondary machining or polishing to meet industrial standards, which adds time and cost and narrows the efficiency gains of AM alone. Furthermore, not all engineering-grade materials are available or certified for use in additive manufacturing platforms, particularly in highly regulated sectors such as aerospace and defence.

When Not to Use Additive Manufacturing

- High-Volume Jobs: Subtractive manufacturing is typically more cost-effective for large-scale production.

- Precision Surface Requirements: CNC machining provides a superior finish quality and consistency from the outset.

- Material Restrictions: AM may not support the specific material grade or alloy needed for a critical application.

In short, AM is a powerful tool—but not the right one for every situation. The key is knowing when it makes sense to use it and when traditional methods will better meet the project’s requirements.

The Ben Machine Approach: Expertise in Evaluating Manufacturing Paths

Ben Machine doesn’t take a one-size-fits-all approach. Each job is evaluated based on the best-fit process or combination of processes.

For prototyping or casting, AM might be the right choice. For tight-tolerance work, CNC machining works better. And when needed, both are used together.

With experience in SLA printing, investment casting, and high-precision CNC machining, Ben Machine helps customers make strategic decisions that save time and money without sacrificing quality.

Our strength lies in striking a balance between innovation and pragmatism. Rather than chasing trends, Ben Machine adopts technology that brings measurable benefits to our customers’ ultimate goals.

Future Outlook: Trends in Additive and Subtractive Manufacturing

The integration of additive and subtractive manufacturing will grow as materials improve and machines become more capable.

Expect to see:

- Wider adoption of hybrid workflows

- Advances in material science (e.g., bio-based composites, stronger polymers)

- AI-driven systems that choose the optimal process path

- Greater connectivity between CAD software and shop floor equipment

In the future, design engineers may rely on simulation tools that recommend not only which features to machine versus print but also how to structure timelines and budgets accordingly.

Shops like Ben Machine are already preparing for this shift by investing in both technology and talent.

Need advice on how to make the right manufacturing choice for your next project? Reach out to Ben Machine for expert guidance on combining additive and subtractive manufacturing in a cost-effective, precision-driven way.